Essential Guide to Selecting the Perfect Serigraphy Equipment

Selecting the right serigraphy machine can make the difference between professional-quality prints and mediocre results. Whether you're starting a printing business or upgrading your existing setup, understanding the key factors in choosing serigraphy equipment is crucial for success. This comprehensive guide will walk you through everything you need to know about selecting the ideal serigraphy machine for your specific needs.

Understanding Serigraphy Machine Types

Manual Serigraphy Presses

Manual serigraphy machines remain popular among beginners and small-scale operators. These presses offer excellent control over the printing process and are perfect for learning the fundamentals of screen printing. They typically feature adjustable pressure settings and can accommodate various frame sizes. While they require more physical effort, manual presses are cost-effective and provide great precision for detailed work.

The durability of manual serigraphy machines is noteworthy, with many lasting decades when properly maintained. They're ideal for small runs and custom projects where attention to detail is paramount. Additionally, manual presses take up less space and are more portable than their automated counterparts.

Semi-Automatic Systems

Semi-automatic serigraphy machines bridge the gap between manual and fully automatic systems. These machines feature powered print heads while requiring manual loading and unloading of materials. They significantly reduce operator fatigue and increase production speed compared to manual presses. Semi-automatic systems often include features like adjustable print speed, stroke length, and squeegee pressure.

These machines are perfect for medium-sized operations looking to boost productivity without massive investment. They maintain good print quality while offering faster throughput than manual systems. Many models also include micro-registration capabilities for precise multi-color printing.

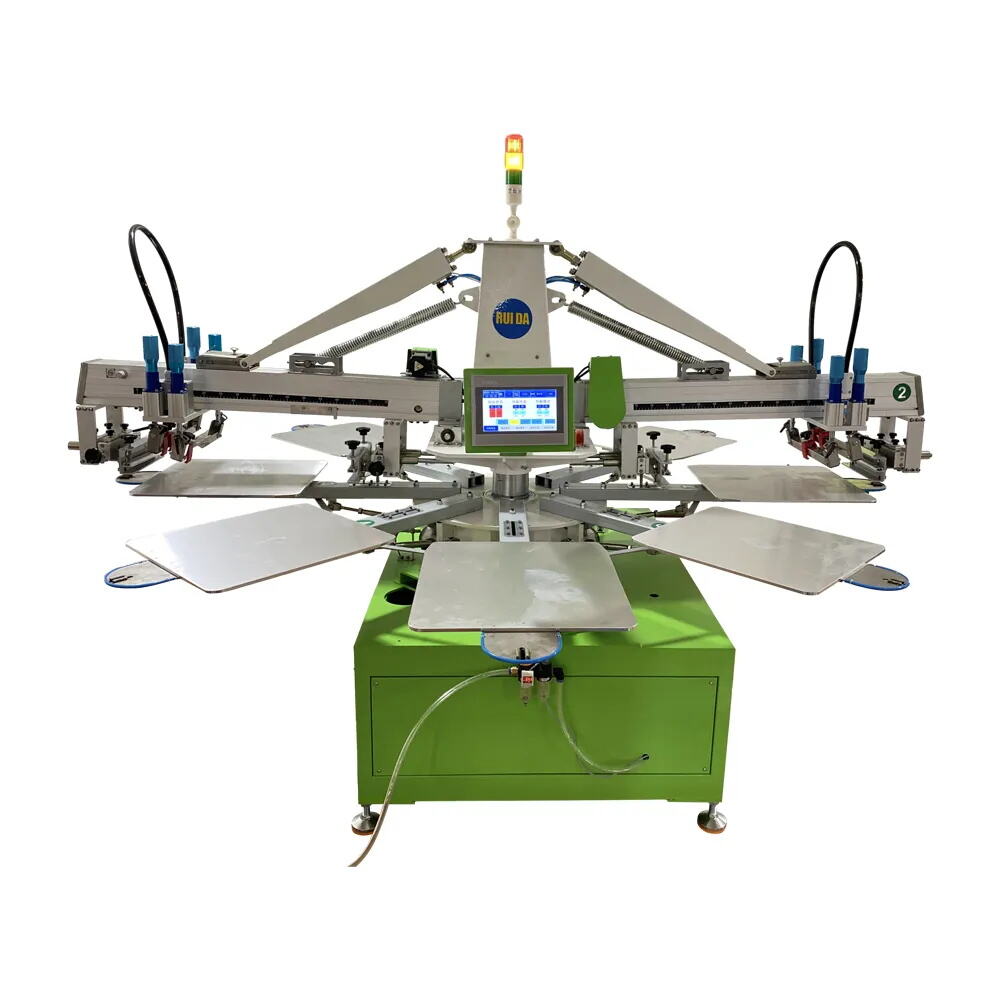

Automatic Printing Systems

For high-volume production, automatic serigraphy machines are the go-to choice. These sophisticated systems handle everything from material loading to printing and unloading with minimal operator intervention. They feature advanced control systems, precise registration, and consistent print quality across long runs.

While requiring significant initial investment, automatic systems dramatically increase production capacity and reduce per-unit costs. They're equipped with features like automatic screen cleaning, flash cure units, and conveyor dryers for complete production automation.

Technical Specifications to Consider

Print Area and Frame Compatibility

The maximum print area and frame size compatibility are crucial factors in choosing a serigraphy machine. Consider your typical project requirements and future growth plans when evaluating these specifications. Most professional machines accommodate standard frame sizes, but specialty projects might require specific dimensions.

Look for machines with adjustable frame holders and multiple print head options. This flexibility allows for various substrate sizes and helps future-proof your investment. Some advanced systems offer quick-change frame adapters for rapid setup between different job specifications.

Registration and Alignment Features

Precise registration is essential for quality multi-color printing. Modern serigraphy machines should include micro-registration adjustments for fine-tuning print alignment. Look for systems with tool-free registration controls and positive lock mechanisms to maintain settings during production runs.

Advanced registration systems might include laser alignment guides, digital positioning displays, or automated registration features. These tools significantly reduce setup time and improve print accuracy, especially for complex multi-color designs.

Production Capacity Analysis

Output Requirements

Understanding your production volume needs is critical in selecting the right serigraphy machine. Calculate your current and projected output requirements, considering factors like average order size, typical turnaround times, and peak season demands. This analysis helps determine whether a manual, semi-automatic, or automatic system best suits your operation.

Consider not just the machine's maximum theoretical output but also practical production rates accounting for setup time, maintenance, and operator breaks. Some machines offer quick-change features that can significantly impact real-world productivity.

Workflow Integration

Your serigraphy machine should integrate smoothly with existing workflow processes. Consider factors like loading height, operator access, and material handling requirements. The machine's footprint and installation requirements must align with your available space and facility layout.

Modern serigraphy machines often include digital interfaces for production tracking and maintenance scheduling. These features can enhance operational efficiency and help maintain consistent quality standards across production runs.

Investment Considerations

Total Cost of Ownership

When budgeting for a serigraphy machine, look beyond the initial purchase price. Consider ongoing costs like maintenance, spare parts, power consumption, and operator training. More automated systems typically have higher upfront costs but may offer lower per-unit production costs over time.

Factor in the machine's expected lifespan and reliability record. Quality manufacturers often provide comprehensive warranties and readily available support services, which can significantly impact long-term operational costs.

Return on Investment Timeline

Calculate your expected return on investment based on production capacity, market demand, and operating costs. Consider how quickly increased efficiency and output quality can offset the initial investment. Some manufacturers offer financing options or leasing programs that can help manage cash flow while upgrading equipment.

Remember to account for potential revenue growth from improved capabilities and production capacity. High-quality equipment can open new market opportunities and allow for premium pricing on superior output.

Frequently Asked Questions

What's the ideal starter serigraphy machine for a small business?

For small businesses, a quality manual or entry-level semi-automatic serigraphy machine is often the best choice. These machines offer a good balance of cost, control, and output capacity while allowing operators to develop essential skills. Look for models with micro-registration capabilities and sturdy construction for long-term reliability.

How much space is needed for a professional serigraphy setup?

Space requirements vary significantly by machine type. Manual presses might need as little as 50 square feet, while automatic systems could require 200-300 square feet or more, including space for material storage and workflow movement. Always factor in additional space for auxiliary equipment like dryers and exposure units.

What maintenance is required for serigraphy machines?

Regular maintenance includes daily cleaning of print surfaces, weekly lubrication of moving parts, and monthly inspection of mechanical components. Automatic systems require additional attention to electronic controls and pneumatic systems. Establishing a preventive maintenance schedule is crucial for maintaining print quality and extending equipment life.

How do I determine the right number of print stations needed?

The number of print stations depends on your typical job requirements. Consider factors like average colors per design, production volume, and turnaround times. Most businesses start with 4-6 stations for basic multi-color work, while advanced operations might need 8-12 stations for complex designs and higher throughput.