ยกระดับศิลปะการพิมพ์ด้วยนวัตกรรมซีริกราฟ

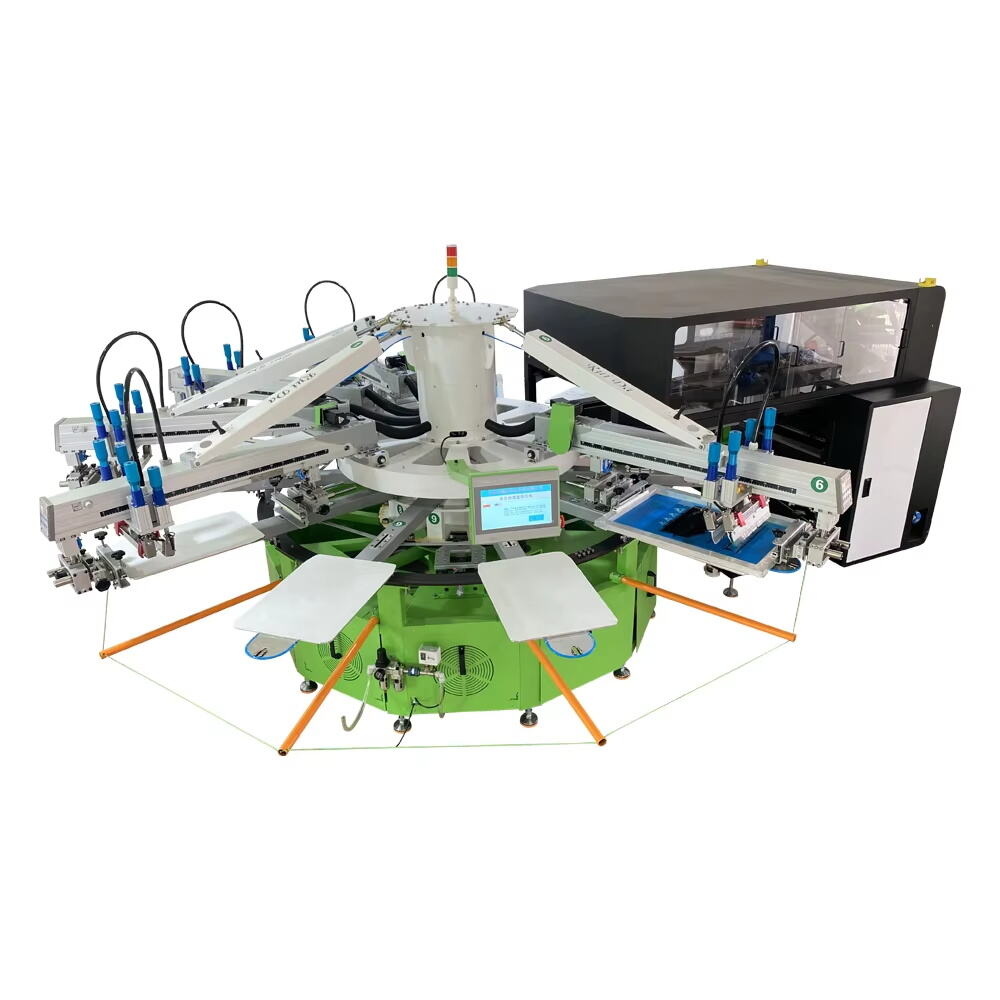

ในอุตสาหกรรมการพิมพ์ที่เปลี่ยนแปลงตลอดเวลา การอยู่ข้างหน้าหมายถึงการยอมรับเครื่องมือที่ผสมผสานความแม่นยำกับความหลากหลายได้อย่างลงตัว เครื่องพิมพ์ซีริกราฟ เปลี่ยนแปลงวิธีการพิมพ์แบบดั้งเดิมด้วยการผนวกรวมระบบอัตโนมัติและระบบควบคุมดิจิทัลขั้นสูง ตั้งแต่การปรับแรงตึงของผ้าไหมอย่างแม่นยำไปจนถึงการส่งหมึกอัจฉริยะ ระบบเหล่านี้ช่วยให้ผู้เชี่ยวชาญด้านการพิมพ์สามารถสร้างทั้งงานศิลปะที่ละเอียดอ่อนและผลงานที่มีคุณภาพสม่ำเสมอในปริมาณมาก โดยการเลือกระบบที่เหมาะสม เครื่องซิลksกราฟี , สตูดิโอและผู้ผลิตสามารถเปิดโลกแห่งความคิดสร้างสรรค์ใหม่ๆ ในขณะที่ปรับกระบวนการทำงานให้มีประสิทธิภาพมากยิ่งขึ้น ตั้งแต่ขั้นตอนแรกจนถึงขั้นตอนสุดท้าย ทำให้โครงการทุกโครงการ ไม่ว่าจะเป็นโปสเตอร์ที่ผลิตในจำนวนจำกัด หรือเสื้อผ้าที่ผลิตเป็นพันชิ้น ต่างก็ผ่านมาตรฐานสูงสุดด้านคุณภาพและความมีประสิทธิภาพ

ประสิทธิภาพการผลิตที่เพิ่มขึ้น

การรวมเข้ากับกระบวนการทำงานที่ราบรื่น

เครื่องพิมพ์ซิลค์สกรีนสามารถผสานรวมเข้ากับชุดโปรแกรมออกแบบยอดนิยมและซอฟต์แวร์ RIP ได้อย่างราบรื่น ช่วยให้สามารถนำเข้างานพิมพ์แบบเลเยอร์ได้โดยตรงโดยไม่ต้องแปลงไฟล์ด้วยตนเอง เครื่องมือจัดตำแหน่งหน้าจออัตโนมัติใช้เซ็นเซอร์ออปติคัลเพื่อปรับเทียบค่าลงทะเบียนภายในระดับไมครอน ช่วยลดข้อผิดพลาดในการตั้งค่าและการสูญเสียวัสดุ การตั้งค่างานที่ปรับแต่งได้จะบันทึกพารามิเตอร์ที่เหมาะสมที่สุดของคุณ เช่น ประเภทหมึก ความเร็วของไม้ปาดน้ำ และเวลาพัก ทำให้สามารถเริ่มงานซ้ำได้เพียงแค่กดปุ่ม รายงานการผลิตขั้นสูงจะติดตามปริมาณงานแบบเรียลไทม์ ช่วยให้ผู้จัดการสามารถปรับตารางเวลาได้อย่างมีประสิทธิภาพ การผสานรวมในระดับนี้ไม่เพียงแต่ช่วยลดระยะเวลาดำเนินการ แต่ยังช่วยให้ผู้ปฏิบัติงานที่มีทักษะสามารถมุ่งเน้นไปที่งานสร้างสรรค์ได้มากกว่าการปรับเปลี่ยนทางกลไก

ระยะเวลาการผลิตที่รวดเร็ว

เมื่อลูกค้าต้องการตัวอย่างงานพิมพ์อย่างรวดเร็วหรือสั่งงานเร่งด่วน ทุกชั่วโมงมีความสำคัญ เครื่องพิมพ์ซิลค์สกรีนรุ่นใหม่ล่าสุดมาพร้อมอุโมงค์อบแบบสองสถานี และโมดูล UV ที่ช่วยให้หมึกแห้งตัวทันที ทำให้ไม่ต้องรอการแห้งตัวตามธรรมชาตินาน ระบบสายพานลำเลียงความเร็วแปรผันสามารถปรับจูนให้สอดคล้องกับหัวพิมพ์ เพื่อรักษาประสิทธิภาพการผลิตที่สม่ำเสมอ แม้ในสภาวะการผลิตสูงสุด ระบบคิวอัจฉริยะช่วยให้สามารถพิมพ์หลายดีไซน์ต่อเนื่องกันได้โดยไม่ต้องแทรกแซงด้วยมือ ผลลัพธ์ที่ได้คือการลดคอขวดระหว่างขั้นตอนการพิมพ์และการตกแต่งอย่างมีนัยสำคัญ ทำให้ธุรกิจสามารถให้คำมั่นสัญญาว่าจัดส่งงานภายในวันเดียวกันหรือวันถัดไป โดยไม่กระทบต่อความเข้มข้นของสีและความสมบูรณ์ของงานพิมพ์

คุณภาพการพิมพ์ยอดเยี่ยม

การทากาวซิลค์สกรีนอย่างสม่ำเสมอ

ความสม่ำเสมอในการพิมพ์จำนวนมากเป็นสิ่งสำคัญอย่างยิ่งต่อชื่อเสียงของแบรนด์ เครื่องพิมพ์ซิลค์สกรีนใช้ปั๊มหมึกที่ปรับเทียบความแม่นยำไว้ล่วงหน้า ซึ่งสามารถจ่ายปริมาณหมึกที่แน่นอนในแต่ละจังหวะการทำงาน เพื่อป้องกันการพิมพ์หมึกมากเกินไปหรือไม่เพียงพอ หน้าจอที่มีแรงดึงสูงจะช่วยป้องกันการหย่อนตัวที่อาจทำให้การเคลือบหมึกไม่สม่ำเสมอ ในขณะที่คานปรับระดับอัตโนมัติรับประกันการไหลเวียนของหมึกที่ราบรื่นทั่วทั้งเฟรม เซ็นเซอร์ตรวจสอบที่ติดตั้งภายในจะตรวจจับการเปลี่ยนแปลงของความหนืดและปรับอัตราการไหลให้เหมาะสม เพื่อให้การพิมพ์มีความแม่นยำสมบูรณ์แบบ การควบคุมที่ละเอียดเช่นนี้ทำให้ได้ผลลัพธ์ที่เหมือนกันทุกชิ้น ตั้งแต่ชิ้นแรกจนถึงชิ้นสุดท้าย ช่วยป้องกันการต้องแก้ไขงานใหม่หรือสั่งทำซ้ำที่ก่อให้เกิดค่าใช้จ่ายสูง

การสร้างสีที่คมชัด

ความสามารถในการผสมสีพันธ์โทน (Pantone) ให้ตรงเป๊ะ หรือพัฒนาสีเฉพาะตัวที่ออกแบบมาโดยเฉพาะ คือจุดเด่นที่สำคัญของเครื่องพิมพ์ซีริกราฟี (Serigraphy Machines) ชุดหัวจ่ายหมึกแบบหลายโซน (Multi-zone ink manifolds) จะส่งหมึกเฉพาะทาง เช่น หมึกสีนีออน สีมุก หรือเรืองแสง ตรงไปยังยางปาด (squeegee) ทันที โดยไม่ต้องผสมด้วยมือซึ่งอาจทำให้เกิดความแปรปรวน อัลกอริทึมหน้าจอโทนระดับขั้นสูง (Advanced halftone screening algorithms) จะแยกโทนสีไล่ระดับออกเป็นจุดเล็กๆ นับพันจุด เพื่อให้ได้การเปลี่ยนผ่านของสีที่เนียนแม้บนเนื้อผ้าที่หยาบ ระบบปรับโปรไฟล์สีอัตโนมัติ (Adaptive color profiling) จะปรับเทียบสีให้เหมาะสมกับวัสดุพื้นฐานที่แตกต่างกัน เพื่อให้มั่นใจได้ว่าความสดใสของแต่ละเฉดสีจะคงเดิมไม่ว่าจะพิมพ์ลงบนผ้าฝ้าย โพลีเอสเตอร์ หรือพลาสติกพิเศษ

การลงทุนระยะยาวที่คุ้มค่า

ลดค่าใช้จ่ายในการบำรุงรักษา

แม้ว่าการบำรุงรักษาจะหลีกเลี่ยงไม่ได้สำหรับทุกระบบเครื่องจักร แต่เครื่องพิมพ์ซิลค์สกรีนได้ลดต้นทุนแรงงานและอะไหล่ผ่านการออกแบบอันชาญฉลาด อุปกรณ์ยึดผ้าไหมแบบปลดเร็วและชิ้นส่วนที่เปลี่ยนได้โดยไม่ต้องใช้เครื่องมือ ช่วยลดเวลาในการทำความสะอาดและการเปลี่ยนชิ้นส่วนลงได้ถึง 50% การตรวจสอบแบบครบวงจรจะคอยตรวจสอบแรงดันปั๊ม กระแสไฟฟ้าของมอเตอร์ และแรงตึงของผ้าไหมตลอดเวลา เพื่อแจ้งเตือนผู้ปฏิบัติงานเมื่อมีปัญหาเล็กน้อยก่อนที่จะลุกลาม ตารางบำรุงรักษาเชิงพยากรณ์สามารถเข้าถึงได้ผ่านแดชบอร์ดที่เชื่อมต่อกับระบบคลาวด์ เพื่อให้มั่นใจว่าการบำรุงรักษาตรงกับช่วงเวลาที่หยุดการผลิต—เพิ่มประสิทธิภาพการใช้งานเครื่องสูงสุดและปกป้องผลกำไรของคุณ นอกจากนี้ ความสามารถในการวินิจฉัยปัญหาจากระยะไกลยังช่วยให้ช่างเทคนิคสามารถแก้ไขปัญหาจากระยะไกลได้ ช่วยลดการเดินทางและการหยุดชะงักของการให้บริการ

ความทนทานและความเชื่อถือได้

เครื่องพิมพ์สกรีนถูกสร้างขึ้นจากโครงสร้างอัลลอยด์ที่ผ่านการเสริมความแข็ง และระบบคู่มือเชิงเส้นเกรดอุตสาหกรรม ซึ่งทนต่อการสึกหรอที่เกิดจากการใช้งานความเร็วสูงในแต่ละวัน ชุดถังใส่หมึกและใบปาดถูกเคลือบด้วยสารป้องกันการกัดกร่อนที่สามารถต้านทานสารทำความสะอาดที่มีฤทธิ์กัดกร่อนสูง ช่วยยืดอายุการบำรุงรักษา พร้อมทั้งมีอุปกรณ์เสริมด้านความปลอดภัยแบบซ้ำซ้อน เช่น สวิตช์หยุดฉุกเฉินและวาล์วระบายแรงดันเกิน เพื่อปกป้องทั้งผู้ใช้งานและอุปกรณ์ภายใต้สภาวะการใช้งานที่หนักหน่วง นอกจากนี้ โมเดลหลายรุ่นยังมีการรับประกันเพิ่มเติมและโปรแกรมฝึกอบรมภาคสนามที่ช่วยเสริมสร้างมาตรฐานการปฏิบัติที่ดีที่สุด ทำให้เครื่องพิมพ์ของคุณทำงานได้อย่างมีประสิทธิภาพสูงสุดด้วยการหยุดชะงักที่น้อยที่สุด

การปรับแต่งและเสรีภาพทางความคิดสร้างสรรค์

ตัวเลือกการออกแบบที่หลากหลาย

เครื่องพิมพ์ซิลค์สกรีน (Serigraphy Machines) ช่วยให้คุณก้าวข้ามข้อจำกัดของการพิมพ์แบบดั้งเดิม การตั้งค่าระยะยกแบบปรับได้ (snap-off) ช่วยให้พิมพ์บนพื้นผิวที่ไม่เรียบหรือแข็งทื่อได้ ในขณะที่อุปกรณ์เสริมแบบหมุน (rotary attachments) สามารถจัดการกับสิ่งของทรงกระบอก เช่น ขวดหรือถ้วย โมดูลพิเศษรองรับกระบวนการทำงานแบบผสมผสาน (hybrid processes) ที่รวมการพิมพ์แบบสกรีนกับเทคโนโลยีอิงค์เจ็ทดิจิทัล เพื่อเพิ่มลูกเล่นเฉพาะจุดหรือพิมพ์ข้อมูลแบบเปลี่ยนแปลงได้ (variable data printing) ชุดซอฟต์แวร์ที่ถูกพัฒนาต่อยอดมีอัลกอริทึมการจัดเรียงชั้นขั้นสูงเพื่อเพิ่มประสิทธิภาพการใช้วัสดุและลดของเสีย ความสามารถเหล่านี้ช่วยให้นักออกแบบสามารถทดลองใช้เนื้อผ้า ชั้นวัสดุ และเทคนิคตกแต่งใหม่ๆ สร้างวัฒนธรรมนวัตกรรมที่ทำให้ผลิตภัณฑ์ของคุณสดใหม่และน่าสนใจอยู่เสมอ

ความยืดหยุ่นในการผลิตแบบ Batch เล็ก

ในยุคสมัยที่เน้นการปรับแต่งเฉพาะบุคคล การผลิตจำนวนน้อยและแบบตามคำสั่งซื้อเป็นสิ่งที่สำคัญมากขึ้น เครื่องพิมพ์ซิลค์สกรีนสามารถรองรับการผลิตเป็นล็อตเล็กที่สุดถึง 5 หน่วยโดยไม่ต้องใช้เวลามากในการตั้งค่าหรือเกิดของเสียจำนวนมาก อุปกรณ์ยึดตะแกรงแบบเปลี่ยนเร็ว และการจัดเก็บสูตรการตั้งค่าไว้ในจุดศูนย์กลาง จะช่วยให้การตั้งค่าต่างๆ มีความสม่ำเสมอระหว่างงานต่างๆ หน่วยความจำในตัวเครื่องสามารถจัดเก็บโปรไฟล์ของโครงการที่ผ่านมาได้หลายพันโครงการ ช่วยให้เรียกคืนและนำกลับมาใช้ใหม่ได้อย่างรวดเร็ว ความคล่องตัวนี้ทำให้สตูดิโอสร้างสรรค์สามารถพัฒนาชิ้นงานต้นแบบได้อย่างรวดเร็ว ตอบสนองเทรนด์เล็กๆ ที่เกิดขึ้น และเสนอทางแก้ปัญหาที่ปรับแต่งเฉพาะบุคคลเพื่อสร้างมูลค่าสูงกว่า—ทั้งหมดนี้ยังคงไว้ซึ่งประสิทธิภาพด้านต้นทุน

ความยั่งยืนและการปฏิบัติที่เป็นมิตรต่อสิ่งแวดล้อม

การใช้หมึกอย่างมีจิตสำนึกต่อสิ่งแวดล้อม

เครื่องพิมพ์ซิลค์สกรีนหลายรุ่นรองรับวัสดุสิ้นเปลืองที่เป็นมิตรต่อสิ่งแวดล้อม ตั้งแต่หมึกที่ใช้น้ำเป็นฐาน ไปจนถึงตัวทำละลายสูตรทางเลือกที่สกัดจากถั่วเหลือง ระบบวัดปริมาณอย่างแม่นยำและระบบหมุนเวียนปิดช่วยลดการพ่นหมึกเกินความจำเป็นและของเสียจากหมึกได้สูงสุดถึง 30% ทำให้ทรัพยากรถูกใช้อย่างประหยัดและมีประสิทธิภาพ หน่วยดูดซับอากาศแบบกรองอากาศช่วยจับสารประกอบอินทรีย์ระเหยตั้งแต่ต้นทาง ส่งผลให้อากาศในสถานที่ทำงานดีขึ้น และช่วยให้การดำเนินงานของคุณสอดคล้องกับข้อกำหนดด้านสิ่งแวดล้อมที่เข้มงวด นอกจากนี้ ผู้ผลิตบางรายยังมีโครงการรีไซเคิลหมึกที่สามารถกู้คืนสีส่วนเกินเพื่อนำกลับมาใช้ใหม่ได้ ช่วยส่งเสริมโมเดลการผลิตแบบหมุนเวียน

การดำเนินงานที่ประหยัดพลังงาน

วิศวกรรมสีเขียวมีขอบเขตที่กว้างกว่าการใช้สิ้นเปลือง ไดรฟ์ปรับความถี่แบบแปรผันจะปรับกำลังมอเตอร์ตามความต้องการแบบเรียลไทม์ ลดการใช้ไฟฟ้าในช่วงที่เครื่องไม่ทำงานหรือมีภาระต่ำ โหมดพักเครื่องแบบตั้งโปรแกรมได้จะปิดชิ้นส่วนเสริม เช่น ตัวทำให้เย็นและหลอด UV เมื่อไม่ได้พิมพ์อยู่จริง รุ่นที่รองรับพลังงานแสงอาทิตย์มีอินเวอร์เตอร์ PV แบบบูรณาการที่สามารถใช้งานพลังงานหมุนเวียนในพื้นที่ได้โดยตรง การจัดการพลังงานอัจฉริยะเหล่านี้ไม่เพียงแต่ช่วยลดคาร์บอนฟุตพรินต์ของคุณ แต่ยังลดค่าใช้จ่ายด้านพลังงาน ทำให้การพิมพ์ที่ยั่งยืนเป็นกลยุทธ์ที่มีความสมเหตุสมผลทางการเงิน

คำถามที่พบบ่อย

เครื่องพิมพ์แบบซิลค์สกรีนต้องการการบำรุงรักษาอย่างไรบ้าง?

การตรวจสอบตามปกติรวมถึงการปรับเทียบแรงตึงของหน้าจอ การหล่อลื่นส่วนเลื่อนกลไก และการตรวจสอบตัวกรองหมึก โดยรอบการล้างส่วนใหญ่เป็นระบบอัตโนมัติ ช่วยลดแรงงานคน

ระดับความยากในการเรียนรู้สำหรับผู้ปฏิบัติงานใหม่อยู่ในระดับใด?

อินเทอร์เฟซหน้าจอสัมผัสที่ใช้งานง่ายและตัวช่วยตั้งค่าแบบมีคำแนะนำ ช่วยให้ผู้ปฏิบัติงานสามารถเชี่ยวชาญฟังก์ชันพื้นฐานภายในไม่กี่ชั่วโมง การฝึกอบรมจากผู้ผลิตยังช่วยเพิ่มประสิทธิภาพการใช้งานให้เร็วยิ่งขึ้น

เครื่องพิมพ์ซีริกราฟสามารถใช้งานกับวัสดุพิเศษได้หรือไม่

ได้ ความดันยางปาด (squeegee pressure) สามารถปรับได้ พร้อมใช้งานกับตะแกรงหลายระดับ (screen meshes) และตัวเลือกหมึกพิเศษ ทำให้สามารถพิมพ์บนผ้า โลหะ พลาสติก ไม้ และอื่นๆ

เครื่องพิมพ์ซีริกราฟสามารถปรับขนาดให้เหมาะกับธุรกิจทุกขนาดได้หรือไม่

ได้อย่างแน่นอน ตั้งแต่เครื่องขนาดเล็กสำหรับวางโต๊ะในสตูดิโอขนาดเล็กไปจนถึงสายการผลิตอัตโนมัติแบบหลายสถานีสำหรับโรงงานที่ผลิตจำนวนมาก มีรุ่นที่เหมาะสมกับทุกความต้องการ