Understanding Manual Press Capacity for Beginner Projects

Matching machine size to projected order volume

Choosing the right manual screen printing machine size is crucial for meeting projected order volumes efficiently. First, estimating the number of prints required per day helps in selecting an appropriately sized machine, with manual screen printing machines typically producing between 50 to 200 prints per hour, depending on design complexity. Assessing the workshop layout for available space and accommodating future growth is also essential. Lastly, examining customer demands and market trends enables predictions of seasonal fluctuations affecting order volume, ultimately influencing the choice of machine size. An integrated approach ensures the smooth operation and scalability of your manual screen printing setup.

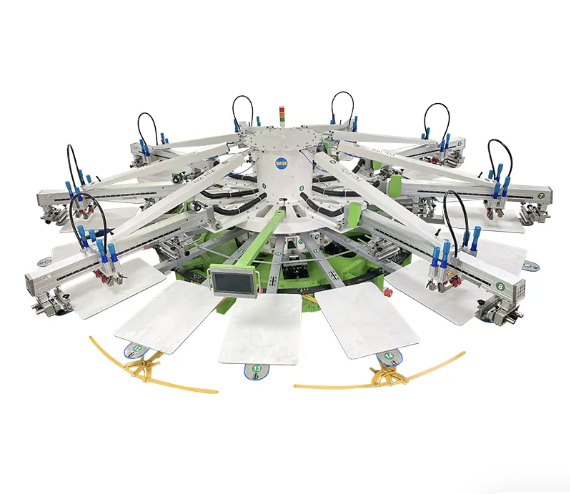

4-color vs 1-station configurations explained

Understanding the difference between 4-color and 1-station configurations can significantly impact printing outcomes for beginners. The 4-color configuration allows printing multiple colors in one go, supporting intricate designs with fewer passes and enhancing production efficiency. On the other hand, the 1-station configuration offers simplicity and is better suited for low-volume projects focusing on single-color prints. When deciding which to use, consideration should be given to business goals, project diversity, and desired print quality. By aligning machine configurations with future business projections, one can optimize both capacity and creativity in beginner manual screen printing projects.

Balancing versatility with simplicity in entry-level setups

When setting up a beginner-friendly screen printing area, balancing versatility with simplicity is crucial. Features like adjustable screen frames and movable platens can enhance versatility without complicating the printing process for novices. A simple user interface and intuitive controls are vital as they facilitate a smoother learning curve, helping beginners master screen printing techniques effectively. Selecting entry-level manual screen printing machines that offer essential features and flexibility can accommodate a range of projects without overwhelming the user. This balance ensures beginners can tackle various designs while maintaining an efficient, straightforward operation.

Essential Technical Specifications to Prioritize

Spring-clamp head systems for 20x24" screen compatibility

Spring-clamp head systems offer significant advantages for ease of use and quick setup, particularly for larger screens such as the 20x24". These systems allow for swift and secure screen mounting, which is crucial for maintaining productivity and efficiency in a manual screen printing operation. When screens are properly secured, the print quality benefits significantly, reducing inconsistencies and improving the consistency of your output. Statistics in the industry suggest that failure rates can be dramatically decreased by ensuring proper screen tension, underscoring the necessity of effective clamping systems. While alternative clamping options exist, spring-clamp systems are preferred in entry-level scenarios due to their simplicity and effectiveness.

Frame locking mechanisms that maintain registration

Robust frame locking mechanisms play an integral role in preventing registration issues, which are common causes of distorted prints. Having a dependable frame locking system ensures that each screen is properly aligned, which is essential for producing precise and high-quality prints. Real-world examples from established screen printing businesses often highlight the importance of precise registration in achieving professional results. Various locking mechanisms are available in the market, and each offers distinct benefits. In manual screen printing machines, the most effective systems seamlessly maintain registration accuracy, reducing the chance of misalignment during printing.

Base stability requirements for consistent prints

A strong, stable base is foundational to minimizing vibrations during printing, thereby enhancing print consistency and quality. A stable base contributes to the reliability of the printing equipment, and manual screen printers require metrics defining sufficient stability to ensure equipment longevity. Industry studies have shown that manual printing machines can exponentially benefit from solid base construction, which directly correlates to print consistency and reduces wear and tear over time. Aside from inherent machine stability, adjustments can be made to accommodate uneven surfaces or tackle heavy-duty printing tasks, thus ensuring that the printer's performance remains stable across different projects.

User-Friendly Features That Speed Up Mastery

XYZ Micro-Registration Dials for Precise Alignment

Micro-registration dials are essential for achieving precise, multi-color prints without misalignment. These features enable fine adjustments to the screen position, ensuring that each color layer aligns perfectly, thus enhancing print accuracy and quality. Many users have reported that access to such dials significantly improves efficiency and output quality, with testimonials highlighting faster job completion and fewer errors. The easy-to-use design of these dials reduces setup time, allowing swift transitions from design conception to production.

Pivoting Platen Systems Enabling Multi-Surface Practice

Pivoting platen systems facilitate printing on diverse surfaces such as t-shirts, bags, and hoodies, which is crucial for expanding product offerings. This versatility allows screen printers to experiment with different techniques, making it particularly appealing to novices eager to master the craft. Numerous manual screen printing machines feature various platen setups, catering to specific uses—from flat garments to uneven surfaces—ensuring adaptability across multiple applications.

Ergonomic Components Reducing Operator Fatigue

Ergonomic design is integral to enhancing operator efficiency and satisfaction in manual screen printing machines. Components such as adjustable height settings and padded grips can drastically reduce exertion, minimizing operator fatigue over prolonged use. Research consistently indicates that ergonomic equipment leads to increased productivity and reduced physical stress. Top-rated entry-level manual screen printing machines often incorporate these features, making them both user-friendly and conducive to long-term use.

Evaluating Manufacturer Support Systems

Video Training Libraries for Fundamental Techniques

Having comprehensive video training libraries from manufacturers makes learning screen printing more accessible, particularly for beginners who are just getting started. These resources can provide step-by-step instructions, tips, and techniques that help users quickly understand the fundamental principles of manual screen printing. According to industry sources, such training resources play a crucial role in enhancing skill acquisition, thereby significantly reducing the learning curve for new users. I recommend looking for manufacturers known for robust training support, such as Dongguan Ruida Electromechanical Equipment Co., Ltd., which offers extensive video tutorials and guides as part of their support system for screen printing equipment.

Availability of Ready-to-Ship Replacement Parts

Quick access to replacement parts is essential for minimizing downtime in production, ensuring that operations run smoothly without unnecessary delays. Prolonged downtimes can severely affect profitability; for instance, industry statistics show that a single hour of inactivity can significantly impact revenue. As a beginner, it’s wise to keep common replacement parts such as squeegees, screens, and ink cartridges readily available to address any issues that might arise. While choosing a manufacturer, ensure they have an efficient distribution network for spare parts to quickly resolve any equipment concerns and maintain productivity.

Warranty Coverage on Critical Components

Warranty coverage on manual screen printing machines is significant as it provides beginners with security in their investment. A manufacturer's commitment to standing by their product through warranty can boost confidence in the equipment's quality and reliability. Typical warranty terms often cover critical components such as printing platens and frames, which are integral to the machine's operation. It's important to align yourself with manufacturers offering strong warranty policies, as they reflect trustworthiness and indicate that they prioritize the quality of their products. For instance, Dongguan Ruida provides excellent warranty coverage, which underscores their commitment to product excellence.

Practical Considerations for Workshop Implementation

Space Requirements for Safe Operation

When designing a workshop for manual screen printing, ensuring safety and compliance begins with effective space allocation. It's crucial to provide clear pathways and maintain emergency exits as stipulated by safety regulations. Occupational Safety and Health Administration (OSHA) guidelines emphasize the importance of unobstructed walkways and accessible exit routes, which must be integrated into any workshop layout. To maximize efficiency, consider layouts that facilitate quick access to tools and materials while maintaining safe distances between equipment. Strategic placement of equipment, such as presses and exposure units, helps optimize both functionality and safety, creating a seamless workflow that adheres to safety protocols.

Upgrade Paths for Future Expansion

Selecting a manual screen printing machine with future growth in mind is essential to adapting as business needs evolve. Planning for scalability includes considering features such as multi-color capabilities and additional platens, which can integrate into existing setups. These upgrades help cater to increasing demand and complex printing tasks. Maintaining versatility in equipment ensures your workshop remains relevant despite rising production needs. Keeping an eye on technological advancements and industry trends is vital, enabling you to seamlessly expand capacity without significant interruptions.

Recommended Maintenance Routines for Longevity

To ensure the longevity of manual screen printing machines, establishing consistent maintenance routines is vital. Routine tasks such as lubrication and tension adjustments prolong operational life and prevent costly repairs. Industry experts recommend adhering to regular maintenance schedules to avoid breakdowns and keep efficiency high. Beginners can create personalized maintenance routines by evaluating usage patterns and equipment specifics, leading to optimal performance. Such proactive measures not only enhance machine longevity but also reduce downtime, ensuring continuous production and quality output.

FAQ

Why is choosing the right manual screen printing machine size important?

The right machine size ensures that you can efficiently handle projected order volumes, meeting customer demands while accommodating future growth.

What are the benefits of a spring-clamp head system?

A spring-clamp system allows for swift and secure screen mounting, improving productivity, efficiency, and print quality by reducing inconsistencies.

How does ergonomic design impact manual screen printing?

Ergonomic components reduce operator fatigue and improve efficiency, leading to increased productivity and satisfaction during prolonged use.