Cost-Effectiveness and Low Startup Investment

No Electricity or Compressed Air Requirements

Manual screen printing machines don't need electricity or compressed air to run, which cuts down on overhead costs quite a bit. For new businesses just getting started, this means they don't have to invest in all sorts of special utilities right from day one. Since these machines aren't dependent on power hungry equipment, companies save money that can go towards things like advertising campaigns or buying more materials when needed. That's why many small operations opt for manual screen printing setups when trying to manage their budgets carefully in the beginning stages.

Minimal Initial Equipment Costs Compared to Automated Systems

Manual screen printing gear usually costs way less than going all out with automatic machines. That makes it great for small shops or artists working with limited funds. What do most people need to get started? Just a screen, some ink, a squeegee, and maybe a basic frame. These items can typically be picked up without breaking the bank. Plenty of print shops actually got their start this way back when money was tight. Looking at how many businesses have grown from humble beginnings tells us that starting small really works for those wanting to break into screen printing without spending a fortune upfront.

Quick Break-Even Point for New Businesses

Manual screen printing equipment doesn't cost much upfront, which means new businesses hit their break even point faster and start seeing returns on investment sooner than many other options. According to market data from PrintTech Insights, most small shops actually pay back their machine costs after just a handful of print jobs, particularly when they get busy around holidays or special events. When owners know exactly what their materials and labor are costing them, they can price products better too. This helps speed up how quickly money comes back in the door. For startups looking to make money without breaking the bank, manual screen printing remains one of the best bets out there right now.

Compact Footprint and Operational Flexibility

Space-Efficient Designs for Garages/Small Studios

Manual screen printing equipment comes in modular, compact packages that work great in small studios or even home garages. The space saving design means artists and small business owners can make the most of whatever room they have available. Despite the limited footprint, these setups still deliver quality prints that rival bigger machines. For folks who don't have access to large commercial spaces, this kind of flexibility makes all the difference. Creativity doesn't require expensive real estate when the right tools fit comfortably on a modest workbench.

Portability for Mobile Printing Services/Events

Manual screen printing machines are light enough to carry around, which gives businesses real flexibility when it comes to offering mobile services. This means companies can actually expand their markets and come up with some pretty cool promotional stuff on location. Artists who go to events or trade shows really benefit from this portability factor. They're able to tweak what they sell based on what people want right there at the event. When printers take their gear directly to customers instead of waiting for them to come in, brands get noticed more naturally. Plus, face-to-face interactions help build those important relationships with folks who might become regular clients down the road.

Adaptability to Irregular Workspaces

Manual screen printing setups can actually work really well in those weird spaces nobody else thinks about using. People have been setting them up in old warehouses, school gyms, even backyards where traditional equipment just wouldn't fit. The whole point is this flexibility lets different artists work together without worrying about perfect conditions. We've seen groups sharing ink and screens in community centers where space was tight but creativity flourished anyway. These manual machines handle all sorts of odd corners and awkward layouts because they don't require the same straight lines and clean floors that automatic systems need. For anyone trying to make art happen on a budget or in unexpected locations, these setups create something special - an environment where experimentation matters more than perfection, and new techniques get born from necessity rather than fancy technology.

For a robust understanding of Manual Screen Printing Machines options and detailed product specifications, you may explore the **DGRUIDA NS1212-HD Heavy Duty Double-Station Screen Printing Press** [here](#). These tools offer insights into achieving operational flexibility with manual screen prints.

Artistic Control and Customization Capabilities

Tactile Ink Deposit Adjustment for Texture Effects

With manual screen printing, artists get something really special - complete control over how much ink goes onto the fabric. That kind of control lets creative juices flow freely. When they actually touch the screens and feel the ink moving through, it opens up all sorts of possibilities for texture work. The whole process feels different than just pressing buttons on a machine. Artists end up making one-of-a-kind pieces that grab people's eyes because no two ever turn out exactly alike. Playing around with ink amounts means experimenting with all kinds of interesting textures and visual effects that give prints extra depth. For many creators, this hands-on aspect is what makes screen printing so rewarding. Every finished product becomes a genuine expression of what was in their head when they started.

Hand-Pulled Technique for Organic Design Variations

When artists pull squeegees manually on screen printing machines, something special happens. The process just naturally leads to those little creative accidents and variations that no machine can really copy. People love this handmade quality because it feels real, not mass produced. There's an art to it all. Printers can tweak things slightly as they work, maybe adjust pressure here or there, which makes every print subtly different from the next. These small differences matter to customers looking for something truly unique rather than identical copies. That's why hand pulled prints often command higher prices despite taking longer to produce.

Immediate Response to Material Feedback During Printing

When working manually with screen printing, artists get to see right away how various materials react with different inks while they're actually printing. This gives them a chance to tweak things as they go along instead of waiting until the end. What happens is the finished piece ends up closer to what the artist originally imagined, which makes customers happier in the long run. Artists who pay attention to these material responses can quickly fix problems or try out new ideas mid-print, something that really affects how good the final print looks and feels. The back and forth between the person printing and the materials themselves creates a much richer creative process than just following a set formula.

Mechanical Simplicity and Long-Term Reliability

No Complex Electronics or Programming Required

Manual screen printing gear stands out because it's mechanically simple stuff, no fancy electronics or complicated programming needed at all. The basic parts are easy to understand and operate, so artists from beginners to pros can get going without much hassle. What makes this approach great is how accessible it stays while cutting down on those frustrating breakdowns that plague more complex machines. No need to worry about expensive repair bills either since there's just not much that can go wrong compared to all those high tech systems with their endless buttons and screens. That's why many print shops still rely on manual setups even when newer options hit the market every year.

Decades-Long Lifespan with Basic Maintenance

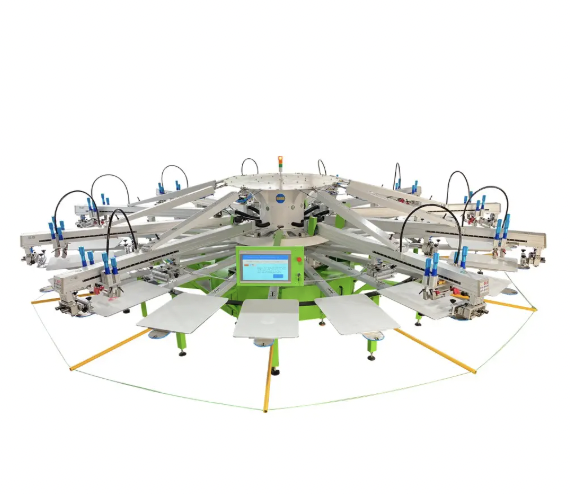

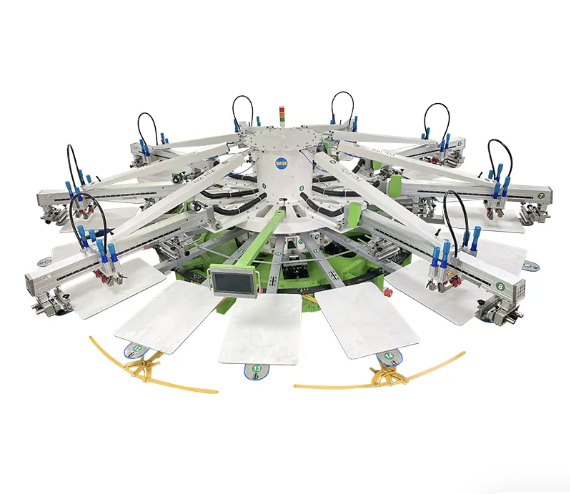

When properly maintained, manual screen printing machines can last for many decades and provide great value to anyone who owns them. Keeping these machines in good condition simply extends how long they stay useful, which makes them a smart investment if someone plans on using them for years. We've seen time and again that manual printers actually cost less to run day to day than newer automated models when kept in top shape. Take the DGRUIDA NS1212-HD as just one real world example. This heavy duty double station press has been known to stick around for ages with regular care. What really stands out about it though is the micro registration system. That little feature alone keeps prints accurate year after year, so operators don't have to constantly adjust things during production runs.

Easy Troubleshooting Without Technical Expertise

Manual screen printing machines are pretty simple to work with, which means most people can figure out what's wrong when something goes off track without needing some kind of expert tech background. When it comes down to fixing things up, this makes for big money saved on repair bills and keeps operations running smoothly instead of grinding to a halt every time there's a hiccup. Most basic problems get sorted out pretty quickly, so the whole printing process doesn't come to a complete standstill. Take the Heavy-Duty Double-Station Screen Printing Press from DGRUIDA for instance – its no-frills design lets anyone handle those little fixes themselves, even if they've never touched one before. For shops that run at full speed all day long, being able to keep going without waiting for someone else to fix stuff really matters for staying productive through tight deadlines and rush orders.

Manual screen printing machines have a real advantage when it comes to simplicity, which makes them pretty reliable and straightforward to operate. Artists working from home studios love them just as much as small print shops looking for something they can count on day after day. These machines don't require fancy tech skills either. A little regular cleaning and oiling keeps them running smoothly for years without breaking down. The design is so intuitive that even newcomers figure out what's wrong when something goes off track. Most problems get fixed right there at the workbench instead of sending the whole machine back for repairs, which means less downtime and more actual printing happening.

Sustainability and Energy Efficiency

Zero Standby Power Consumption

Manual screen printing machines save a lot of energy because they don't need any power when sitting around doing nothing. That simple fact makes them great for cutting down on electricity bills and helping the environment at the same time something that matters more than ever these days. The whole printing business is changing fast toward greener methods, and screen printers just happen to fit right in with this movement. When shops want to go green without sacrificing quality or productivity, many turn to manual screen printing equipment since it sits there quietly without draining the grid when workers take breaks between jobs.

Reduced Material Waste Through Manual Precision

Manual screen printing gives artists much better control over how much ink gets used, so there's generally less wasted material than what happens with automated systems. Because it's done by hand, printers can tweak things on the fly and apply just the right amount of ink where needed, cutting down on leftovers and mess. Print shops that stick with manual methods often find they produce far less waste overall. This matters a lot for the environment too many small studios report slashing their waste output after switching back from machines to manual screens. The difference shows up in trash bins and recycling containers across the industry.

Compatibility with Eco-Friendly Inks/Substrates

Manual screen printing saves energy and works great with those eco-friendly inks and sustainable materials people are talking about these days. As more folks look for green alternatives, this flexibility really comes into play. Research indicates that interest in environmentally friendly printing has been climbing steadily over recent years, and manual screen printing fits right into this trend. Print shops can swap out regular inks for biodegradable ones and start using recycled paper without much hassle at all. Most small businesses find that making these changes doesn't cost them anything extra while still letting them market themselves as environmentally responsible.

[Manual Screen Printing Machines](#) are leading the way in eco-conscious practices within the industry, proving that tradition and sustainability can go hand-in-hand without compromising the quality or integrity of the finished product.

Low-Risk Entry for Small-Scale Production

Ideal for Prototyping/Limited Edition Runs

Manual screen printing works great for artists and designers looking to test out new ideas or create small batches before going all in on big production orders. The process gives them room to play around with different colors and patterns without wasting resources on massive quantities first. A lot of creative businesses actually started this way, making tiny test prints and slowly growing their audience as people got used to their style. What makes manual screen printing machines so valuable is how they let makers put real thought into each piece while still keeping costs manageable. Artists who take advantage of this approach often end up standing out from competitors because their work feels more intentional and crafted rather than mass produced.

No Minimum Order Requirements

Manual screen printing has one major plus point no minimum orders needed at all. That means people can print whatever quantity they want, big or small. This kind of flexibility lets shop owners take on those special requests and tiny batches without worrying about hitting some arbitrary number. Artists working alone and folks selling niche products love this aspect because it allows them to offer exactly what their customers ask for. When businesses need something truly customized, manual screen printing machines just make sense for the job.

Gradual Scaling Without Equipment Overhaul

For businesses looking to scale slowly as orders come in, manual screen printing offers real benefits. Companies don't need to spend tons of cash on expensive machines when they want to boost production capacity. Manual screen printers are pretty flexible too, which helps small operations adapt as they grow. Startups especially appreciate this because they can keep product quality high while experimenting with different designs and colors. When customer demand starts picking up, these businesses simply crank out more units step by step instead of jumping into full scale manufacturing overnight. This approach keeps things manageable and lets them grow at a pace that works for everyone involved.

Conclusion

Manual screen printing remains one of the best options for getting started with minimal risk, especially when producing smaller quantities. What makes this approach so attractive? Well, there's flexibility regarding how many items get printed at once, better control over special edition batches, and the ability to slowly grow operations as needed. Small businesses and independent artists find these features incredibly helpful when building something sustainable over time rather than going all in right away. These machines let folks experiment and create without breaking the bank on equipment costs. Plus, they open doors to customization and environmentally friendly practices that just happen to match what consumers want these days. Many shops report being able to maintain quality while keeping things green, which definitely matters in today's market.

FAQs

What is manual screen printing?

Manual screen printing is a traditional method of printing that uses manually-operated machines without electricity or compressed air, providing flexibility, cost-effectiveness, and artistic control.

How does manual screen printing benefit startups?

Manual screen printing offers low startup costs, quick break-even points, and operational flexibility, making it ideal for entrepreneurs with limited investment capabilities.

Can manual screen printing machinery fit into small studios?

Yes, manual screen printing setups are compact and can easily fit into small studios or home garages, optimizing creative workspace.

Are manual screen printing machines sustainable?

Yes, they are sustainable due to zero standby power consumption, reduced material waste, and compatibility with eco-friendly inks and substrates.