Elevating Print Quality with Smart Equipment Choices

As design standards evolve and production demands increase, choosing the right machine becomes essential for consistent, high-quality serigraphy output. In 2025, leading printing studios, apparel manufacturers, and promotional product companies rely on advanced Machines for Serigraphy Printing to meet complex workflows and varying order volumes. The correct machine enhances productivity, reduces waste, and simplifies multi-color setups. Whether you're a small startup or an established print shop, the right serigraphy machine can be a game-changer.

Understanding Different Machine Types and Their Strengths

Flatbed vs Rotary Serigraphy Machines

Flatbed machines offer precise handling for rigid substrates like metal plates, wood panels, and glassware. Their stable tables allow accurate registration and tight color alignment. For businesses working with diverse products, flatbed Machines for Serigraphy Printing provide flexibility in material handling.

Rotary machines, in contrast, excel in high-volume cylindrical or curved items such as bottles, cans, and cylindrical containers. Units with automatic indexing and wraparound printing capabilities offer fast, consistent results. These machines streamline production when long runs or irregular shapes are required.

Manual, Semi-Automatic, and Fully Automatic Systems

Manual tabletop machines remain popular among designers and small craft studios. These compact Machines for Serigraphy Printing are cost-effective entry points. Semi-automatic models add motorized squeegee or indexing features, increasing throughput without full automation costs.

Fully automatic carousel or inline systems dominate industrial operations. These machines handle multi-station color layering, auto-loading, and real-time quality checks. Though substantial investments, they deliver fast ROI when production volumes are high.

Key Features to Prioritize in 2025 Machines

Precision Registration and Color Accuracy

High-end Machines for Serigraphy Printing include fine-adjustment registration systems with micro-scale control. This precision is critical for multi-color designs, halftone art, and matching Pantone shades. Automated sensors and vision systems eliminate guesswork and reduce setup time.

Consistent print placement and in-line adjustments ensure each unit matches the design exactly, even at scale. Color deviation becomes negligible, making these machines ideal for contract printing and brand assurance.

Built-In Curing and Drying Technologies

Modern serigraphy equipment often comes with integrated flash dryers, conveyor dryers, or UV curing systems tailored to specific ink types. Machines for Serigraphy Printing that combine printing and curing in one workflow minimize handling and speed up production.

Precisely timed curing ensures ink adhesion and prevents blurring. Built-in air filtration and exhaust systems further maintain print quality and working environment safety.

Top Machines in 2025 for Different Business Needs

Entry-Level Flatbed Printers

Brands offering compact flatbeds suitable for small production spaces include models with four-color capability and interchangeable pallets. These Machines for Serigraphy Printing support DTG hybrid integration and offer modular upgrades.

Affordable models deliver solid registration, adjustable flood bars, and automated squeegee action. Their reliability and upgrade paths make them a popular choice among growing businesses.

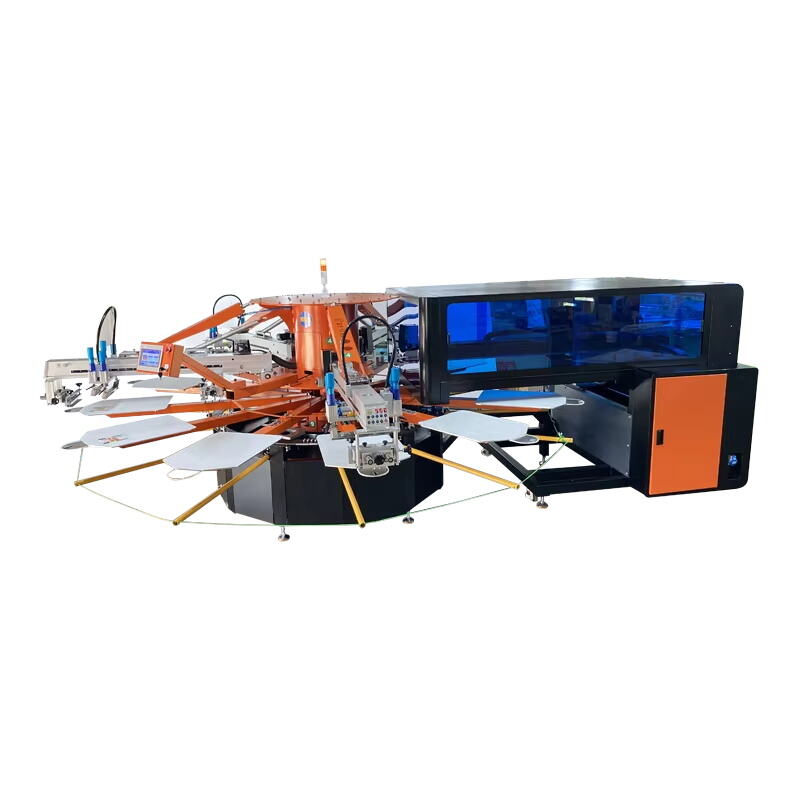

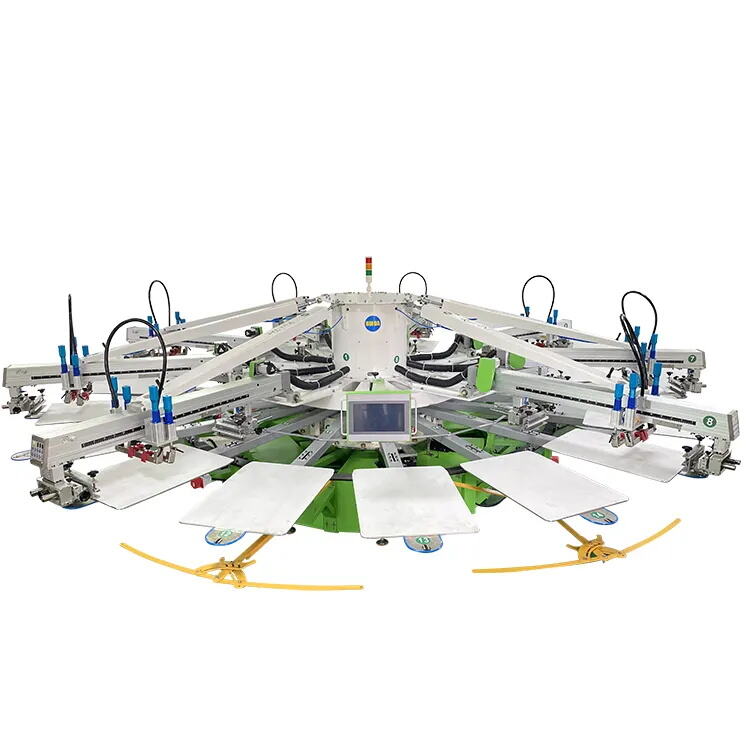

Industrial Multi-Color Carousel Systems

Large carousel presses with 8–12 color heads dominate high-volume apparel and textile printing. These Machines for Serigraphy Printing feature auto-registration, pantograph motors, and full electronic monitoring. Inline flash curing ensures quick color layering without manual intervention.

Such systems can print thousands of garments per hour and support features like inline drying, pneumatic micro-adjustments, and antibacterial lightening. They're essential for major brand fulfillment and large seasonal orders.

Specialized Machines for Unique Applications

Cylindrical and Container Printers

Machines built for bottles, jars, and cans, including vertical drum and roll-to-roll systems, offer precise wraparound printing. These Machines for Serigraphy Printing often include vision-based indexing and vacuum grips to stabilize curved items during ink application.

With fast format changeovers and variable diameter support, they’re ideal for craft beverage producers, cosmetics brands, and promotional goods.

Hybrid Hybrid UV/DTG Systems

Cutting-edge units combining serigraphy with direct-to-garment (DTG) printing provide flexibility between process colors and specialized effects. These Machines for Serigraphy Printing use hybrid platforms to apply base layers via screen, then use DTG for spot details and photographic imaging.

The multi-modal workflow supports small batch runs with high visual impact and diverse ink types—ideal for premium or custom apparel lines.

Operational Considerations and ROI

Evaluating Productivity vs Investment Costs

When selecting Machines for Serigraphy Printing, consider throughput, labor savings, ink usage, and downtime. A bigger machine may require higher upfront cost but reduce per-unit expenses through efficiency. Balancing startup capital with long-term ROI is a smart decision-making process.

Maintenance and Consumables Support

Reliable support and easily sourced parts make a machine a valuable asset. Machines for Serigraphy Printing with robust after-sales service and modular parts ensure reliability. Consider ease of screen changes, ink recirculation systems, and self-cleaning features as part of total cost ownership.

Sustainability and Eco-Friendly Features

Low-Emission Inks and Recycling Systems

Leading Machines for Serigraphy Printing now support water-based, UV, or plastisol recycling loops. Integrated flash systems with low-energy heaters reduce power usage. Automated ink recapture systems minimize waste.

Investing in equipment with sustainable credentials can earn eco-certifications and appeal to conscientious customers while optimizing cost efficiency.

Energy-Efficient Designs

Newer machines incorporate standby modes, variable pumps, and insulated curing tunnels to reduce power consumption. Companies can lower utility bills without sacrificing performance. Energy efficiency proves valuable for seasonal or round-the-clock production.

Future-Proofing Your Print Setup

Software Integration and Industry 4.0 Connectivity

Modern Machines for Serigraphy Printing frequently include IoT functionality, remote diagnostics, and cloud-based production tracking. Integration with ERP systems ensures full control over order workflows and inventory.

Real-time data helps detect wear and optimize scheduling. Predictive maintenance reduces downtime and boosts reliability.

Expandability and Hybrid Workflow Support

Look for additions like chill rollers, stackers, or DTG attachments that can be integrated into existing screen systems. Forward-compatible Machines for Serigraphy Printing allow businesses to grow without replacing entire lines.

Modular designs future-proof investment while supporting emerging print trends.

FAQ

What type of machine is best for small-run printing?

Entry-level flatbed or hybrid screen/DTG machines offer flexibility and cost-effective performance for small batch orders.

How do I choose between manual and automatic machines?

Choose manual or semi-automatic presses when variability is high and run lengths are short. Opt for fully automatic for high-volume stability and speed.

Are maintenance and consumables expensive?

Properly designed Machines for Serigraphy Printing use economical consumables. Modular maintenance options help reduce ongoing costs.

How can I ensure accurate multi-color registration?

Invest in machines with micro-registration systems or vision-assisted sensors. Automated adjustments eliminate manual drift and ensure repeatable placement.

Table of Contents

- Elevating Print Quality with Smart Equipment Choices

- Understanding Different Machine Types and Their Strengths

- Key Features to Prioritize in 2025 Machines

- Top Machines in 2025 for Different Business Needs

- Specialized Machines for Unique Applications

- Operational Considerations and ROI

- Sustainability and Eco-Friendly Features

- Future-Proofing Your Print Setup

- FAQ