Exploring the Intricacies of Modern Serigraphy Techniques

Serigraphy, an art form rooted deeply in history, has transformed remarkably with the introduction of advanced technology. Among these innovations, machine serigraphy stands out as a revolutionary process combining traditional screen printing methods with automation. But what exactly is machine serigraphy, and how does it operate to meet the growing demands of various industries? This comprehensive exploration will uncover the details behind machine serigraphy, its operational mechanisms, and its growing relevance in today’s printing landscape.

Understanding Machine Serigraphy Process

Machine serigraphy is an automated form of screen printing that utilizes mechanized systems to replicate images or designs onto various surfaces. Unlike manual screen printing, which requires human intervention for each step, machine serigraphy leverages equipment that controls ink application, screen movement, and substrate positioning with precision. This method improves speed and consistency, making it suitable for high-volume production.

At its core, machine serigraphy involves pushing ink through a finely woven mesh screen that has been prepared with a stencil blocking out areas where ink should not pass. The machine’s automated squeegee presses ink through the open areas of the screen, depositing the design onto the material beneath. This process can be repeated multiple times to apply different colors, achieving complex and vibrant results.

Moreover, machine serigraphy incorporates advanced registration systems that ensure exact alignment of screens during multi-color printing processes. This technological enhancement minimizes the risk of misalignment, a common issue in manual screen printing, thereby increasing print accuracy and overall product quality.

Materials and Equipment Used in Machine Serigraphy

The success of machine serigraphy depends heavily on the materials and equipment employed. Screens are typically made from polyester or nylon mesh stretched over a frame. The mesh count—number of threads per inch—varies based on the detail level required in the print.

In addition to screens, the inks used play a vital role. Machine serigraphy can accommodate various ink types, including plastisol, water-based, and discharge inks, each offering distinct finishes and durability.

In particular, plastisol inks are favored in machine serigraphy for their opacity and vibrancy, especially on dark-colored fabrics. Water-based inks, while less vivid, offer softer finishes and are preferred for eco-friendly applications. Discharge inks remove dye from fabric, replacing it with ink color, resulting in a vintage look with excellent durability.

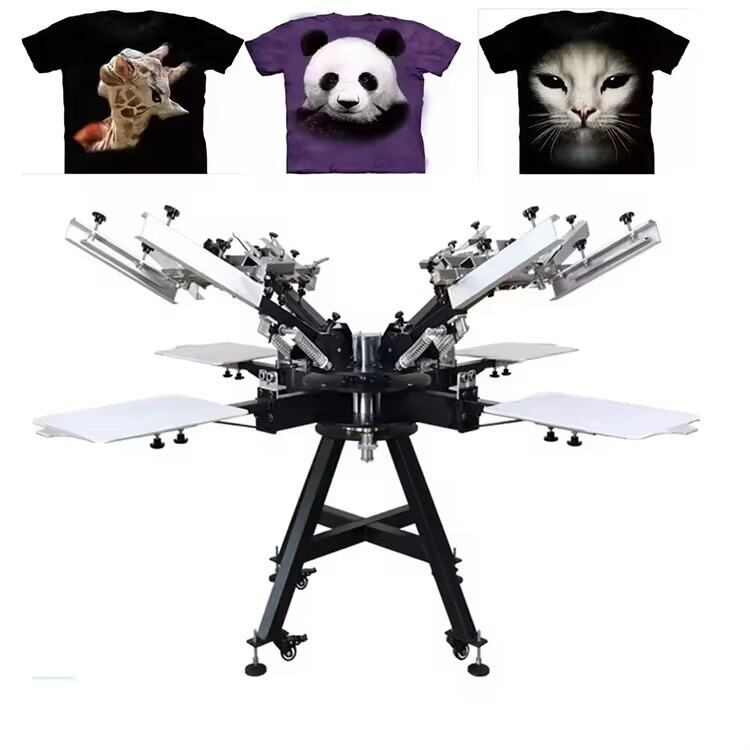

The machinery itself ranges from semi-automatic to fully automatic systems, often equipped with features like conveyor belts, automatic screen cleaning, and drying units. These enhancements ensure consistent quality and reduce manual labor.

The choice between semi-automatic and fully automatic machine serigraphy depends largely on production volume and budget constraints. Semi-automatic machines require some operator involvement, providing a balance between manual control and automation. Fully automatic machines, by contrast, allow for continuous operation with minimal human intervention, ideal for large-scale manufacturing.

Operational Advantages of Machine Serigraphy

Enhanced Production Efficiency

One of the primary advantages of machine serigraphy lies in its ability to significantly increase production throughput. Automated screen printing machines can operate continuously, producing large quantities of printed items faster than traditional manual methods. This is especially beneficial for businesses needing to fulfill large orders within tight deadlines.

The precise control over ink deposition and screen alignment minimizes errors and reduces waste, which contributes to cost-effectiveness. Moreover, automated setups allow for quick changes between designs, helping companies respond swiftly to market trends or customer demands.

Furthermore, the repeatability of the process ensures uniformity across batches, a critical factor in branding and product consistency. This predictability helps reduce costly mistakes and returns that could occur due to printing flaws.

Superior Print Quality and Consistency

Machine serigraphy guarantees high-quality prints with remarkable consistency across batches. The uniform pressure applied by mechanical squeegees ensures even ink distribution, avoiding common issues like blotches or fading.

Furthermore, automation reduces the risk of human error during the printing process. This leads to sharp, vibrant designs that maintain their integrity even after multiple washes or prolonged use. For industries such as apparel, signage, and promotional products, this level of quality is indispensable.

Additionally, machine serigraphy enables finer detail reproduction compared to some other printing methods, due to the precision in mesh tension and ink application. This advantage allows businesses to offer intricate designs that appeal to consumers seeking unique visual experiences.

Applications and Industry Use Cases of Machine Serigraphy

Diverse Substrate Compatibility

Machine serigraphy excels in versatility, as it can print on a wide array of substrates including textiles, plastics, glass, metal, and wood. This flexibility makes it ideal for various sectors such as fashion, packaging, advertising, and industrial labeling.

By selecting appropriate inks and screens, manufacturers can tailor their machine serigraphy processes to meet specific requirements. For example, printing on flexible fabrics differs substantially from applying designs onto rigid surfaces like metal panels, yet machine serigraphy accommodates both with ease.

In addition to traditional materials, machine serigraphy is also being used increasingly on unconventional substrates like ceramics and even electronic devices, broadening its industrial appeal.

Customization and Large-Scale Production Balance

Machine serigraphy strikes a balance between customization and large-scale production. While digital printing often dominates for highly detailed, low-volume jobs, machine serigraphy is preferred for medium to large runs where durability and cost-efficiency are priorities.

It allows businesses to offer personalized products without sacrificing the benefits of bulk manufacturing. This adaptability is especially attractive in markets where consumers demand unique yet affordable designs.

The ability to switch quickly between designs on automated machines enables small batch production alongside large runs, making machine serigraphy a versatile choice for diverse business models.

FAQ About Machine Serigraphy

What differentiates machine serigraphy from traditional screen printing?

Machine serigraphy automates many manual steps in the screen printing process, using machinery to apply ink and handle substrates. This results in faster production speeds, higher consistency, and reduced human error compared to traditional methods.

Can machine serigraphy handle complex, multi-color designs?

Yes, machine serigraphy is capable of producing intricate multi-color prints by using multiple screens and layers. Automated registration systems ensure precise alignment of colors for sharp, vibrant results.

What types of materials can be printed using machine serigraphy?

A wide range of substrates can be printed, including textiles, plastics, glass, metal, and wood. By choosing suitable inks and screens, machine serigraphy adapts to various surface types efficiently.

How does machine serigraphy contribute to sustainability efforts?

Machine serigraphy can incorporate eco-friendly inks and operate with energy-efficient equipment. These sustainable practices reduce environmental impact while delivering high-quality prints.