Understanding Modern Print Screen Technology for Apparel Production

The landscape of custom apparel manufacturing has been revolutionized by advanced print screen machines that combine precision, efficiency, and versatility. These sophisticated systems have transformed how businesses approach garment customization, enabling everything from small boutique operations to large-scale production facilities to create professional-quality printed apparel. The latest print screen machines incorporate cutting-edge features that ensure consistent quality while maximizing productivity.

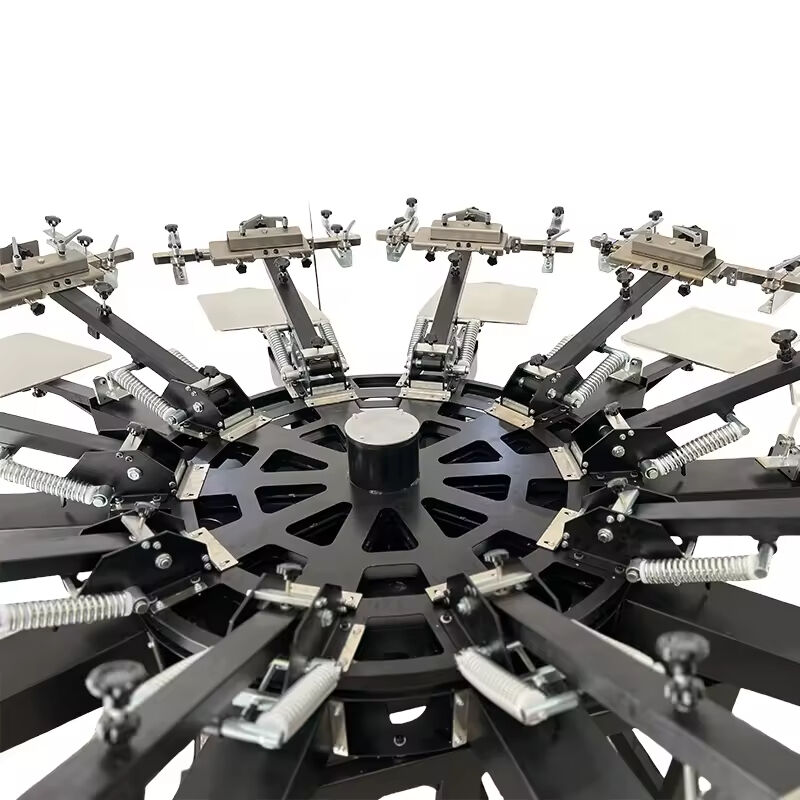

Essential Components of Professional Print Screen Equipment

Advanced Registration Systems

Modern print screen machines feature sophisticated registration systems that ensure perfect alignment across multiple colors and designs. These systems utilize micro-adjustment mechanisms and digital controls to achieve precise positioning, eliminating common issues like misalignment or ghosting. The integration of optical registration markers further enhances accuracy, allowing operators to achieve professional results consistently.

High-Performance Print Heads

The print head assembly is the heart of any screen printing system. Contemporary print screen machines employ innovative print head designs that optimize ink distribution and pressure control. These components are engineered with durable materials and precision mechanisms that maintain consistent quality even during extended production runs. Advanced models feature adjustable print head pressure settings to accommodate different fabric types and ink formulations.

Automated Control Systems

Digital control interfaces have become standard features on professional print screen machines. These systems allow operators to store and recall job settings, monitor production parameters, and make real-time adjustments to ensure optimal print quality. Automated controls also help maintain consistent production speeds while reducing operator fatigue and potential human error.

Performance Features That Define Quality Print Screen Equipment

Production Speed and Efficiency

Leading print screen machines are designed to maximize throughput without compromising quality. High-speed indexing systems and efficient platen movement ensure smooth transitions between print stations. Advanced models can achieve impressive production rates of several hundred pieces per hour while maintaining precise registration and consistent print quality. These capabilities are essential for businesses looking to scale their operations and meet increasing demand.

Versatility in Application

Modern print screen machines offer remarkable versatility in handling different garment types and printing techniques. From standard t-shirts to specialized materials like performance wear, these systems can accommodate various fabric thicknesses and compositions. Multiple print station configurations allow for complex multi-color designs, while quick-change features facilitate rapid job transitions.

Quality Control Mechanisms

Built-in quality control features help operators maintain consistent output throughout production runs. Print screen machines now incorporate sensors and monitoring systems that track critical parameters such as print pressure, registration accuracy, and ink flow. These technologies help identify potential issues before they affect production quality, reducing waste and improving efficiency.

Maintenance and Longevity Considerations

Regular Maintenance Requirements

Professional print screen machines are built for durability, but proper maintenance is essential for optimal performance and longevity. Regular cleaning protocols, lubrication schedules, and component inspections help prevent unexpected downtime and maintain print quality. Modern systems often include maintenance tracking features that alert operators when service is required, helping to establish proactive maintenance routines.

Wear Component Management

Understanding the lifecycle of wear components is crucial for maintaining consistent print quality. Screen frames, squeegees, and other consumable parts require regular inspection and replacement. Leading print screen machines are designed for easy access to these components, simplifying maintenance procedures and reducing service time.

Upgrade Potential

The modular design of modern print screen machines allows for future upgrades and modifications. This flexibility enables businesses to adapt their equipment as technology advances or production requirements change. Many manufacturers offer upgrade packages that can enhance capabilities without requiring complete system replacement.

Environmental and Safety Features

Sustainable Operation Practices

Environmental considerations have become increasingly important in print screen machine design. Modern systems incorporate features that minimize ink waste, reduce energy consumption, and support eco-friendly production practices. Advanced filtration systems help manage fumes and particulates, while efficient heating elements optimize curing processes while reducing energy usage.

Operator Safety Systems

Safety features are paramount in professional print screen machines. Emergency stop systems, light curtains, and physical guards protect operators during production. Advanced models include automated safety checks that prevent operation when protective features are compromised, ensuring a secure working environment while maintaining productivity.

Investment Considerations and ROI

Initial Cost Analysis

When evaluating print screen machines, considering the total cost of ownership is essential. While initial purchase prices vary significantly, factors such as production capacity, feature set, and build quality directly impact long-term value. Professional-grade machines typically offer better return on investment through higher productivity, reduced waste, and longer service life.

Operational Cost Management

Understanding ongoing operational costs helps businesses optimize their investment in print screen equipment. Modern machines offer features that reduce ink consumption, minimize setup time, and improve energy efficiency. These capabilities contribute to lower per-piece production costs and improved profitability over time.

Frequently Asked Questions

What factors should I consider when choosing a print screen machine?

Consider your production volume requirements, available space, types of garments you'll be printing, and desired print capabilities. Also evaluate the manufacturer's support network, warranty terms, and availability of replacement parts. Your budget should account for both initial purchase and ongoing operational costs.

How often should print screen machines be serviced?

Professional print screen machines typically require daily cleaning, weekly maintenance checks, and comprehensive quarterly servicing. However, specific maintenance schedules depend on production volume, operating conditions, and manufacturer recommendations. Following prescribed maintenance protocols is essential for optimal performance and longevity.

What type of training is required to operate modern print screen machines?

While modern print screen machines feature user-friendly interfaces, comprehensive operator training is essential. This typically includes understanding basic operation, maintenance procedures, troubleshooting techniques, and safety protocols. Many manufacturers offer training programs and ongoing technical support to ensure optimal equipment utilization.

Table of Contents

- Understanding Modern Print Screen Technology for Apparel Production

- Essential Components of Professional Print Screen Equipment

- Performance Features That Define Quality Print Screen Equipment

- Maintenance and Longevity Considerations

- Environmental and Safety Features

- Investment Considerations and ROI

- Frequently Asked Questions