Mastering Modern Print Screen Technology

The evolution of print screen machines has revolutionized how we approach document reproduction and image transfer in professional settings. These sophisticated devices have become indispensable tools across industries, from manufacturing and textile printing to educational institutions and creative studios. Understanding the fundamental operation of a print screen machine opens doors to efficient production and high-quality output.

Essential Components of Print Screen Systems

Primary Machine Framework

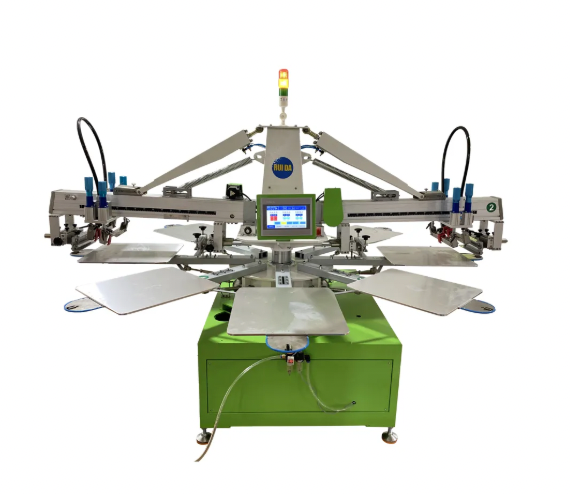

At the heart of every print screen machine lies a robust framework designed to maintain stability during operation. The main structure typically consists of a sturdy metal frame that houses the printing mechanism, ensuring precise alignment and consistent results. The base platform provides support for the printing screen and substrate, while the registration system guarantees accurate positioning for each print cycle.

Screen Assembly and Mesh Selection

The screen assembly represents a critical component of any print screen machine. It consists of a finely woven mesh stretched across a rigid frame, typically made from aluminum or wood. The mesh count, measured in threads per inch, varies depending on the application – finer meshes suit detailed artwork, while coarser screens work better for heavy ink deposits. Professional operators carefully select mesh counts based on their specific printing requirements.

Modern print screen machines often feature quick-release mechanisms for screen attachment, allowing rapid screen changes between production runs. This innovation has significantly improved workflow efficiency and reduced setup times in commercial printing operations.

Operating Procedures and Best Practices

Setup and Calibration Process

Proper setup of a print screen machine begins with careful calibration of all moving parts. Operators must verify the alignment of the print head, adjust pressure settings, and ensure proper off-contact distance between the screen and substrate. These preliminary steps are crucial for achieving consistent print quality and preventing equipment damage.

The registration system requires particular attention during setup. Modern print screen machines feature microregistration adjustments that allow for precise control over image placement. Experienced operators understand that even minimal misalignment can result in rejected prints and wasted materials.

Production Workflow Management

Establishing an efficient workflow is essential for maximizing print screen machine productivity. This includes organizing materials, maintaining clean workstations, and implementing systematic quality control measures. Operators should regularly monitor ink viscosity, screen tension, and equipment settings throughout the production run.

Documentation of machine settings and production parameters helps maintain consistency across multiple operators and shifts. Many contemporary print screen machines include digital interfaces that store preferred settings for different job types, streamlining the setup process for recurring projects.

Maintenance and Troubleshooting Guidelines

Routine Maintenance Protocols

Regular maintenance ensures optimal performance and longevity of print screen machines. Daily cleaning procedures should include thorough screen washing, removal of excess ink, and inspection of moving parts. Operators must pay special attention to squeegee conditions and replace worn components before they affect print quality.

Implementing a preventive maintenance schedule helps identify potential issues before they develop into serious problems. This includes regular lubrication of moving parts, tension checks on belts and drives, and calibration of pressure systems.

Common Issues and Solutions

Even well-maintained print screen machines occasionally encounter operational challenges. Understanding common problems and their solutions enables operators to minimize downtime and maintain production efficiency. Issues like image blurring, incomplete ink transfer, or registration drift often have simple solutions when diagnosed correctly.

Modern print screen machines typically include diagnostic tools that help identify mechanical or electronic issues quickly. Operators should familiarize themselves with these features and maintain detailed maintenance logs to track recurring problems and solutions.

Advanced Features and Automation

Digital Integration Capabilities

Contemporary print screen machines increasingly incorporate digital technologies to enhance precision and efficiency. Computer-to-screen systems enable direct imaging of screens, eliminating the need for traditional film positives. These advanced features reduce setup time and improve registration accuracy.

Automated control systems monitor production parameters and adjust settings in real-time, ensuring consistent quality throughout long production runs. Many machines now offer remote monitoring capabilities, allowing supervisors to track performance metrics and maintenance needs from mobile devices.

Production Optimization Tools

Modern print screen machines come equipped with sophisticated tools for optimizing production efficiency. These include automatic ink dispensing systems, preset programs for different substrate types, and integrated quality control mechanisms. Such features help maintain consistent output while reducing operator fatigue and human error.

Data collection and analysis capabilities enable managers to identify bottlenecks and optimize workflow patterns. This information proves invaluable for scheduling maintenance, planning production runs, and maximizing equipment utilization.

Frequently Asked Questions

How often should print screen machines undergo maintenance?

Professional print screen machines require daily cleaning and inspection, weekly component checks, and monthly comprehensive maintenance. Critical parts should be serviced or replaced according to manufacturer specifications, typically every 3-6 months depending on usage intensity.

What factors affect print quality on screen printing machines?

Print quality depends on multiple factors including screen tension, ink viscosity, squeegee pressure, off-contact distance, and substrate characteristics. Environmental conditions like temperature and humidity also play significant roles in achieving consistent results.

What training is required to operate a print screen machine?

Operators should complete comprehensive training covering machine operation, maintenance procedures, troubleshooting techniques, and safety protocols. Many manufacturers offer certification programs, and ongoing professional development helps operators stay current with new technologies and best practices.