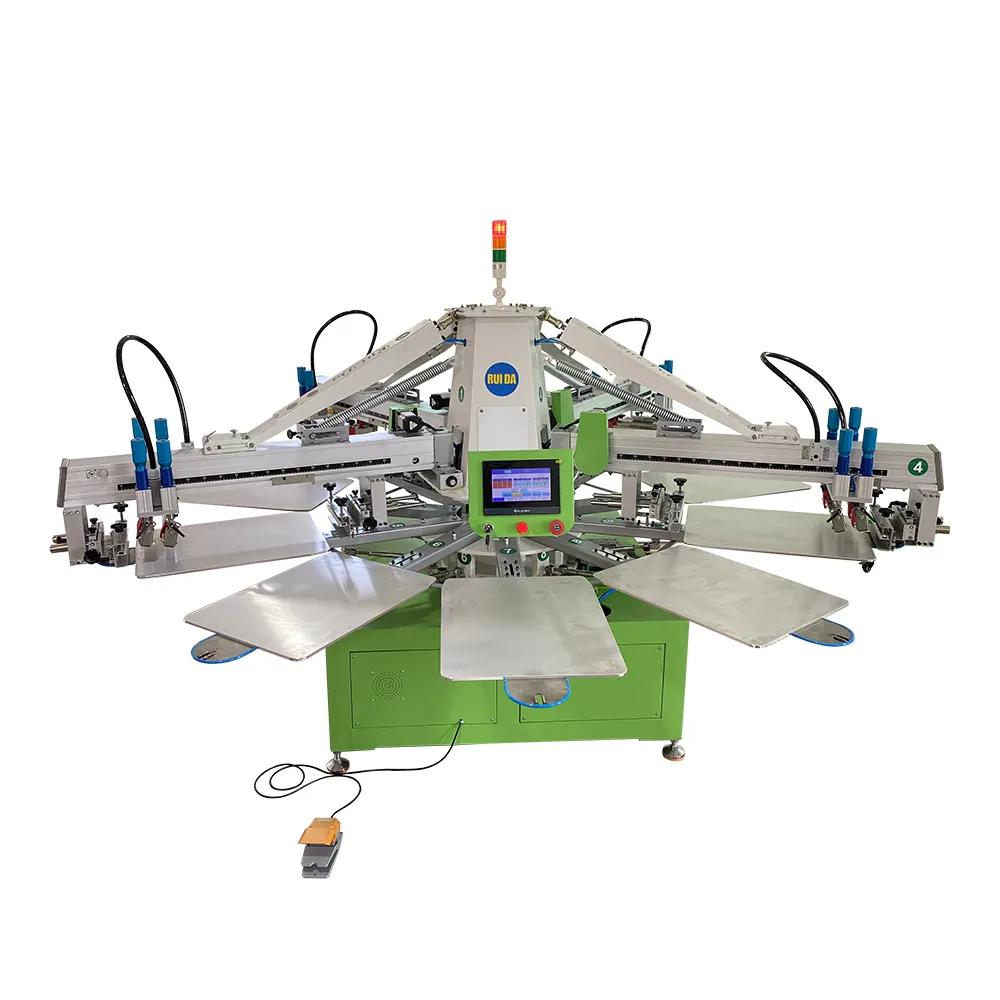

Las industrias manufactureras modernas dependen cada vez más de soluciones de impresión eficientes y precisas para satisfacer las crecientes demandas de producción. Entre estas tecnologías, las máquinas automáticas de serigrafía han surgido como equipos esenciales en múltiples sectores, ofreciendo una calidad constante mientras maximizan el rendimiento. Estos sistemas sofisticados combinan los principios tradicionales de la serigrafía con automatización avanzada, permitiendo a las empresas obtener resultados profesionales a escala industrial. La versatilidad y fiabilidad de las máquinas automáticas de serigrafía las convierten en herramientas indispensables para los fabricantes que buscan mejorar sus capacidades de producción manteniendo la rentabilidad.

Fabricación de textiles y prendas

Producción en masa de prendas

La industria textil representa uno de los mercados más grandes para las máquinas de serigrafía automática, donde la eficiencia y la consistencia son fundamentales. Estos sistemas destacan por imprimir diseños en camisetas, sudaderas y otras prendas con una precisión y velocidad notables. Las instalaciones de fabricación pueden procesar cientos de prendas por hora manteniendo una cobertura uniforme de tinta y una gran intensidad del color. Los sistemas automáticos de registro garantizan una alineación perfecta de múltiples colores, eliminando las variaciones comunes en los procesos de impresión manual.

Las máquinas automáticas de impresión serigráfica ofrecen ventajas significativas para manejar pedidos grandes de artículos promocionales, uniformes corporativos y líneas de ropa al por menor. La aplicación constante de presión y el depósito controlado de tinta resultan en impresiones que cumplen con los estrictos estándares de calidad exigidos por las principales marcas. Además, estos sistemas pueden adaptarse a diversos tipos y grosores de tejidos, lo que los convierte en soluciones versátiles para aplicaciones textiles diversas. Los requisitos reducidos de mano de obra se traducen en menores costos de producción y tiempos de entrega más rápidos para pedidos urgentes.

Aplicaciones Textiles Especiales

Más allá de la impresión estándar en prendas, las máquinas automáticas de serigrafía sirven para aplicaciones textiles especializadas, incluyendo tejidos técnicos, ropa deportiva y textiles industriales. Estas aplicaciones requieren a menudo formulaciones específicas de tintas, como propiedades de absorción de humedad, antimicrobianas o ignífugas. El control preciso que ofrecen los sistemas automatizados garantiza una adecuada adhesión de la tinta y características de rendimiento esenciales para aplicaciones técnicas. Los equipos deportivos y las marcas de ropa deportiva se benefician especialmente de la capacidad de producir estampados que mejoran el rendimiento y que resisten lavados repetidos y un uso intensivo.

Las textiles para el hogar y las telas decorativas también dependen en gran medida de la tecnología de impresión serigráfica automática para patrones, diseños y recubrimientos funcionales. Las cortinas, ropa de cama y materiales para tapicería suelen presentar diseños complejos de múltiples colores que requieren un registro preciso y una calidad constante. La automatización elimina los errores humanos que podrían comprometer la alineación del patrón o la coincidencia de colores en grandes series de producción. Esta fiabilidad hace que las máquinas de impresión serigráfica automática sean esenciales para los fabricantes textiles que abastecen a los mercados de diseño de interiores y mobiliario para el hogar.

Electrónica y Fabricación de Tarjetas de Circuito

Aplicaciones de placas de circuito impreso

La industria electrónica utiliza ampliamente máquinas de serigrafía automáticas para aplicar pasta de soldadura, tintas conductoras y recubrimientos protectores a placas de circuitos. Estas aplicaciones exigen una precisión y repetibilidad extremas, ya que incluso pequeñas variaciones pueden afectar el rendimiento o la fiabilidad de los componentes electrónicos. Los sistemas modernos de serigrafía automática incorporan sistemas de alineación visual y funciones de microposicionamiento para lograr tolerancias micrométricas. La presión constante de la rasqueta y la liberación controlada de la tinta garantizan una cobertura uniforme en circuitos complejos.

Los procesos de ensamblaje mediante tecnología de montaje superficial se benefician especialmente de la impresión automática por pantalla para la aplicación de pasta de soldadura. Las máquinas pueden manejar componentes de paso fino y diseños de circuitos densos, al mismo tiempo que mantienen depósitos precisos de pasta necesarios para uniones de soldadura confiables. Los sistemas de tinta con control de temperatura y los parámetros programables de la rasqueta optimizan la reología de la pasta para aplicaciones específicas. Este nivel de control reduce significativamente las tasas de defectos y mejora la fiabilidad general de los ensambles electrónicos.

Electrónica flexible y interruptores de membrana

Las máquinas automáticas de impresión serigráfica desempeñan un papel fundamental en la fabricación de electrónica flexible, interruptores de membrana y paneles táctiles utilizados en electrónica de consumo y sistemas de control industrial. Estas aplicaciones requieren la impresión de tintas conductivas de plata, materiales dieléctricos y recubrimientos protectores con un control preciso del espesor. Los sistemas automatizados garantizan propiedades uniformes de las capas, esenciales para el rendimiento eléctrico y la durabilidad. La capacidad de imprimir sobre sustratos flexibles abre posibilidades para diseños innovadores de productos en tecnología portátil y aplicaciones de pantallas curvas.

La fabricación de dispositivos médicos incorpora cada vez más electrónica impresa para sensores, equipos de diagnóstico y sistemas de monitorización de pacientes. Máquinas de serigrafía automáticas proporcionan la fiabilidad y trazabilidad requeridas para aplicaciones médicas, cumpliendo al mismo tiempo con estrictas normas regulatorias. El entorno de impresión libre de contaminación y los parámetros del proceso documentados satisfacen los requisitos de gestión de calidad en la fabricación sanitaria.

Industria de señalización y gráficos

Producción de señalización comercial

La producción de señalización de gran formato depende en gran medida de máquinas automáticas de serigrafía para crear gráficos exteriores duraderos, exhibidores publicitarios en puntos de venta y señalización arquitectónica. Estas aplicaciones requieren tintas resistentes a los rayos UV y sustratos resistentes a las inclemencias del tiempo que soporten condiciones ambientales adversas. Los sistemas automatizados garantizan un espesor y cobertura de tinta uniformes en paneles grandes, manteniendo al mismo tiempo la precisión del color durante largas tiradas de producción. La capacidad de imprimir tintas blancas y especiales permite posibilidades creativas que no son alcanzables con tecnologías de impresión digital.

Los entornos minoristas se benefician de las capacidades de impresión automática por serigrafía para crear exhibiciones vibrantes, pancartas y materiales promocionales. Los depósitos gruesos de tinta que permite la serigrafía ofrecen opacidad y saturación de color superiores en comparación con otros métodos de impresión. Los sistemas automáticos de registro garantizan un alineamiento preciso de múltiples colores incluso en materiales de gran formato, manteniendo los estándares profesionales requeridos para la representación de marca. La rentabilidad de la serigrafía para cantidades medias y grandes la convierte en la preferida para materiales de campañas minoristas.

Aplicaciones Especiales y Gráficas Decorativas

Las máquinas automáticas de impresión serigráfica permiten la producción de gráficos especiales, incluyendo materiales reflectantes, tintas fosforescentes y recubrimientos texturizados para efectos visuales únicos. Las señales de seguridad y las aplicaciones de control de tráfico requieren materiales retrorreflectantes impresos con registro preciso para mantener los estándares de visibilidad. La deposición controlada de tinta y la aplicación constante de presión garantizan una incorporación óptima de las microesferas reflectantes y una mayor durabilidad. Estas aplicaciones especializadas suelen tener precios superiores, lo que hace que la producción automatizada sea económicamente atractiva.

La impresión en vidrio arquitectónico y baldosas cerámicas representa una aplicación creciente de las máquinas de serigrafía automática en mercados decorativos. Estos sustratos requieren procesos de cocción a alta temperatura que exigen formulaciones específicas de tintas y parámetros de aplicación. Los sistemas automatizados ofrecen la repetibilidad necesaria para igualar colores y patrones en múltiples lotes de producción. La capacidad de imprimir recubrimientos funcionales, como superficies antirreflejantes o de fácil limpieza, añade valor a los productos arquitectónicos.

Fabricación Industrial e Impresión Funcional

Producción de Componentes Automotrices

La industria automotriz utiliza ampliamente máquinas automáticas de impresión serigráfica para paneles de instrumentos, superficies de control y componentes de acabados exteriores. Estas aplicaciones requieren tintas duraderas que resistan la exposición a la radiación UV, temperaturas extremas y productos químicos presentes en los limpiadores. Los sistemas de impresión automatizados garantizan una calidad constante en producciones de alto volumen, cumpliendo con normas de calidad automotriz rigurosas. La capacidad de imprimir elementos funcionales, como sensores táctiles capacitivos, directamente sobre los componentes reduce la complejidad del ensamblaje y mejora la fiabilidad.

Las aplicaciones críticas de seguridad en la fabricación automotriz se benefician de la trazabilidad y el control de procesos que ofrecen las máquinas de impresión serigráfica automáticas. Los sensores de airbag, los componentes del sistema de frenos y los sistemas de gestión del motor a menudo incorporan circuitos impresos o sensores que requieren parámetros documentados de fabricación. Las capacidades automatizadas de recopilación de datos y monitoreo de procesos cumplen con los requisitos de gestión de calidad automotriz y garantizan la consistencia del producto durante todos los ciclos de producción.

Aplicaciones de embalaje y etiquetado

La impresión de envases representa un área importante de aplicación para las máquinas automáticas de serigrafía, especialmente para productos premium que requieren efectos especiales o propiedades funcionales. El embalaje cosmético suele incluir recubrimientos texturizados, tintas metálicas o elementos táctiles que mejoran el atractivo de la marca y la experiencia del usuario. Los sistemas automatizados garantizan la aplicación uniforme de estos materiales especiales, al tiempo que mantienen los niveles de productividad necesarios para la fabricación de bienes de consumo. La capacidad de integrar la serigrafía con otros procesos de decoración permite crear soluciones de envasado únicas.

Las aplicaciones de embalaje funcionales incluyen recubrimientos barrera, funciones anti-falsificación y elementos de embalaje inteligente que requieren parámetros precisos de impresión. Las máquinas automáticas de serigrafía ofrecen el control y la repetibilidad necesarios para estas aplicaciones exigentes, al tiempo que mantienen la velocidad requerida en entornos de producción de embalajes. Los sistemas de tinta con control de temperatura y los controles ambientales garantizan un rendimiento óptimo de los materiales funcionales durante todo el proceso de impresión.

Preguntas frecuentes

¿Qué industrias se benefician más de las máquinas automáticas de serigrafía?

La industria textil y de confección lidera el uso de máquinas de impresión serigráfica automática, seguida de cerca por la fabricación electrónica para aplicaciones en placas de circuito. La producción de señalización y gráficos, la fabricación de componentes automotrices y las industrias del embalaje también representan segmentos de mercado importantes. Estas industrias se benefician de la combinación de alta capacidad de producción, calidad constante y rentabilidad que ofrecen las máquinas de impresión serigráfica automática.

¿Cómo mejoran las máquinas de impresión serigráfica automática la eficiencia de producción?

Las máquinas automáticas de impresión serigráfica aumentan significativamente las velocidades de producción al tiempo que reducen los requisitos de mano de obra y el desperdicio de materiales. Los sistemas avanzados de registro eliminan el tiempo de configuración entre trabajos y garantizan una calidad constante sin ajustes manuales. Los parámetros programables permiten a los operadores almacenar configuraciones óptimas para diferentes productos, reduciendo los tiempos de cambio y manteniendo la consistencia entre lotes de producción. La menor dependencia del nivel de habilidad del operador también minimiza las variaciones de calidad.

¿Cuáles son las ventajas técnicas clave de los sistemas automatizados de impresión serigráfica?

Las máquinas modernas de impresión serigráfica automática ofrecen un control preciso de la presión, un ángulo de rasqueta constante y velocidades de carrera programables que garantizan depósitos de tinta uniformes. Los sistemas de alineación por visión proporcionan una precisión de registro a nivel de micrones para aplicaciones a todo color. Los controles ambientales mantienen condiciones óptimas de impresión independientemente de los factores externos. Las capacidades de registro de datos permiten el monitoreo del proceso y la trazabilidad de calidad requerida en entornos de fabricación certificados.

¿Qué materiales de sustrato funcionan mejor con las máquinas automáticas de impresión serigráfica?

Las máquinas automáticas de impresión serigráfica admiten una amplia gama de sustratos, incluyendo textiles, plásticos, metales, vidrio, cerámicas y productos de papel. Los requisitos clave son la estabilidad dimensional durante la impresión y la compatibilidad con la química de la tinta. Los sustratos flexibles se benefician de sistemas de sujeción al vacío, mientras que los materiales rígidos pueden requerir accesorios especializados. El grosor del sustrato y la textura de la superficie influyen en la selección de la rasqueta y en los ajustes de presión para lograr una calidad óptima de impresión.

Tabla de Contenido

- Fabricación de textiles y prendas

- Electrónica y Fabricación de Tarjetas de Circuito

- Industria de señalización y gráficos

- Fabricación Industrial e Impresión Funcional

-

Preguntas frecuentes

- ¿Qué industrias se benefician más de las máquinas automáticas de serigrafía?

- ¿Cómo mejoran las máquinas de impresión serigráfica automática la eficiencia de producción?

- ¿Cuáles son las ventajas técnicas clave de los sistemas automatizados de impresión serigráfica?

- ¿Qué materiales de sustrato funcionan mejor con las máquinas automáticas de impresión serigráfica?