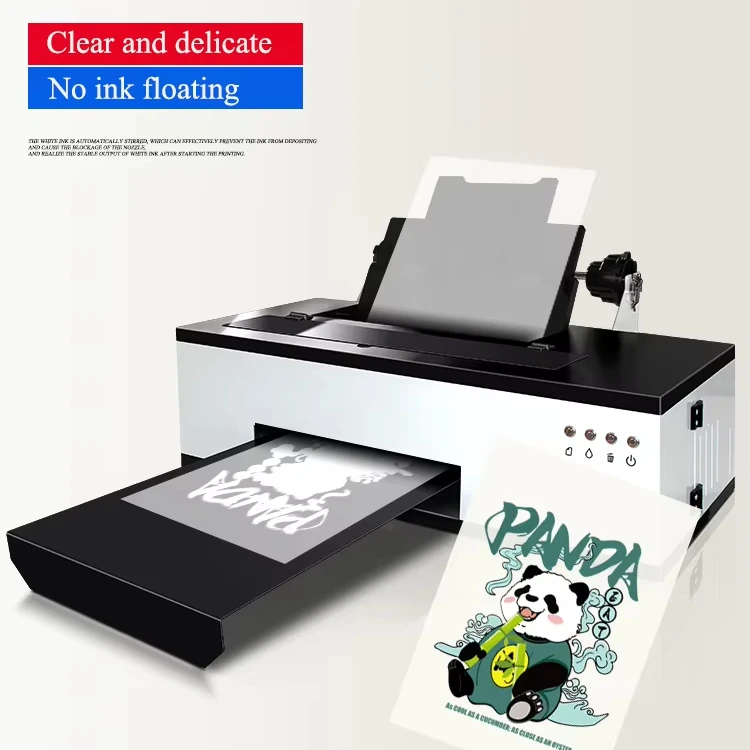

DGRUIDA 5 Layers Screen Printing Drying Cabinet Dryer Machine Max Frame Size 700*1000mm

The DGRUIDA 5-layer screen printing drying cabinet is a professional-grade solution for efficient frame drying and storage. The cabinet's advanced design includes proper ventilation and temperature control to ensure optimal drying conditions for various screen printing materials. Perfect for commercial printing shops, textile manufacturers, and industrial applications, this drying cabinet combines functionality with space efficiency to enhance your screen printing operations.

- Overview

- Related Products

Screen printing drying Cabinet

| Name | 5 layer screen printing drying cabinet 3000W |

| Application | The machine is important equipment in plate-macking, it is used to dry the screen plate after emulsion coated or after washing screen plate. |

| Feature | |

| 1 | Intelligent temperature controller,the temperature can be adjusted freely. |

| 2 | It's smart cabinet is of good sealing. |

| 3 | Adopting newest heat plate with double- heat function,more efficiency |

| 4 | High qulity plate to make temperature of each tray even and correct. |

| Parameter | |

| 1 | Max.screen plate drying quantity: 5pcs |

| 2 | Max.frame size: 700*1000mm |

| 3 | Voltage: 220V |

| 4 | Power: 2000W |

| 5 | Weight: 148 kg |

| 6 | Package size:124*99*117cm |

Screen drying cabinet is an important tool in screen printing. Several procedures need a screen drying cabinet like degreasing screen ,coating emulsion, coating hardener, washout and so on.This machine gives up traditional heating pipe technique to adopt advanced and safe flate carbon fiber heating plate. Professional design, energy saving, safe and easy manipulation, used for drying screen ,shading light, proofing dust and so on.

Features

1.Intelligent temp controlling system. Its temp can be adjusted according to the heat resistance of screen mesh. When the room temp is 77℉ (25℃), its highest temp can reach 172℉ (78℃).

2.The inside installed axial flow fan makes the hot air in circulation, which guarantees an equal temp in cabinet and can improve drying efficiency meanwhile. The axial flow fan (specially used for large computer equipment) can normally be used for about 20000 hours. It usually takes 2-4 minutes to well dry the screens coated with the photosensitive emulsion.

3.It adopts hierarchical (100 levels) temp-adjusting system; users can adjust temp according to ambient temperature and different materials. It can operate according to your set temp next time because of its automatic memorizing function.

4.It is wholly coated without corrosion and dandification. The drawer type is flexible but perfect tight. All kinds of screens can be placed and moved flatly with printed side up to guarantee the adhesive layer smooth.

5.The heating plates are adopted the newest blade and unit type, with double-heat, low power and high heat efficiency. At the same time, it guarantees the temperature of machine even to make the temperature of each floor even and accurate.

6.Total power is 2000W.compared with traditional 3000-8000W cabinet, this machine can save power 70-90%.

7.Constructed by five layers of cabinets, 5 frames below 700*1000mmcan be held at the same time, saving time, improving efficiency.

8.Inner and out sides all adopts electrostatic spraying, professional outlook, easy to clean and no rust.

Instructions

1. Turn on the switch; then the machine will indicate “F000” and the air fan works automatically.

2. Press “+” until to “F070’

3. Place thermometer probe on the third drawer; Check the temp after five minutes.

4. If the temp is not right in your need, you can press “+” or “-” to increase or reduce 10 grades; Awaiting five minutes then check the temp.

5. After adjusting the available temp, the machine will automatically save and memory your set data.

6. It is normal that the “F” or “O” displays alternately when the machine is working.

Reference data: When the room temperature is 77F (25C) or so, close and seal all drawers, ten minutes later after you have set, the temp indicates—

1. Set “F050”, the temp is about 93F (34C)

2. Set “F060”, the temp is about 104F (40C)

3. Set “F070”, the temp is about 115F (46C)

4. Set “F080”, the temp is about 126F (52C)

5. Set “F090”, the temp is about 140F (60C)

6. Set “F100”, the temp is about 167F (75C)

Use very strong and safety plywood case package: