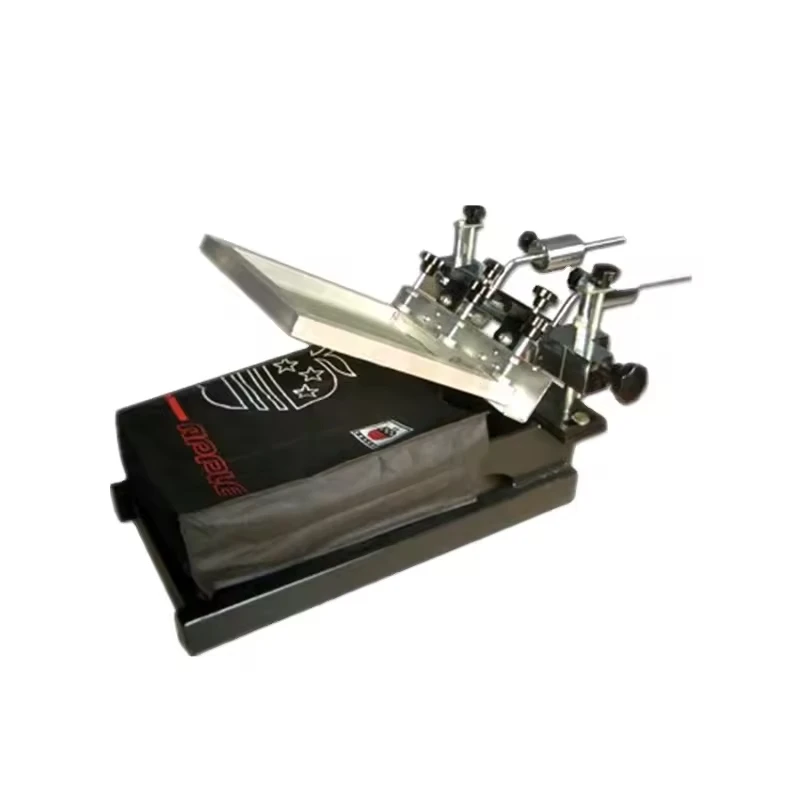

NS103 1 Color 3 Stations Simply Screen Printing Machine Manual Micro-adjustable Screen Printer

This NS103 manual screen printing machine offers precision and versatility for small-scale printing operations. The micro-adjustable design ensures accurate registration and fine-tuning of print positions, making it ideal for printing on t-shirts, bags, and other flat surfaces. Perfect for startups, small print shops, or DIY enthusiasts, this screen printer delivers professional results without the complexity of automated systems.

- Overview

- Related Products

screen printing equipment NS103 1 Color 3 station Micro-Adjustable Screen Printing Machine

color |

1 color |

pallet size |

600x450mm/440x320mm /300x420mm |

station |

3 station |

max frame size |

500x650mm |

net weight |

29KGS |

Gross weight |

32KGS |

packing size |

66x50x25CM&49x21x27cm |

Based on the need of customers and market, our company R&D the 1-1 screen printer, which overcomes shortages of traditional press, such as without micro-devices, only one fixed platen and can not put on the T-shirt, pillow, bag and so on. It is especially suitable for printing non-woven environment-friendly shopping bags.

This equipment includes the main printing device and three platens with different sizes.

screen printing equipment Main Features :

This equipment includes the main printing device and three platens with different sizes.Screwing two bolts, users can replace the shirt board easily to overprint different substrates.

Overprint is a significant feature

The significant feature brings it wide applications, such as T-shirts, pillowcases, non-woven bags, etc.

All-around micro-devices and lock device

Micro-device makes screen and shirt board joint evenly, micro-device up and down with different substrates, also for left and right, back and forth, which ensures the precision of printing.

The lock devices can make every part stable and it also ensures the precision of printing.

The best application for these 1-1 flatbed screen press is to get halftone effect.

Using this micro device, professional printer also can use these press to apply multi-color printing.

With two assistive hammers

Adjusting the position of hammers facilitates rising and falling for screen with different sizes and weights.

Utilizing electrostatic spraying and electroplating, durable, easy clear, no rust.

screen printing equipment Parameters:

Shipping weight:70LB(32KG)

Package size:30"x20"x14"(76x51x36cm)

Printing Head Weight: 22Lb (9.7kg)

Pallet Sizes:

23.6”x17.7” (60x45cm)

17.3"X12.6"(44x32cm)

11.8”x9.4” (30x24cm)

screen printing equipment Installation and Operation

Attention:You should loose the lock devices before installing and then tighten them after your installations.

1. Install the Machine Head.Remove the bolts, put the machine head on to the base support, adjust the proper position and then screw the bolts tightly.

2. Install the Gravity Hammers.

3. Install the Stretched Screen Frame to check whether you have well installed it or not.

4. Adjust the screen plate with its micro adjusting functions, then apply it into printing process.

Q1. About the packing?

A: According to the machine type, if heavy machine, we will pack it in exported wooden case, if light machine, we will pack it in cartons.

Q2. About the payment?

A: If order amount is more than USD5000.00, we can accept T/T 30% as deposit, and 70% before delivery.

Q3. About the trade terms?

A: EXW, FOB, CFR, CNF.

Q4. About the delivery time?

A: According to the machine model and quantity, if hot-selling machine, will be 15 days around.

Q5. About the shipping port?

A: Shenzhen

Q6: About the machines guarantee time?

A : 1 year

Q7. How about your company's quality control?

A.We have a professional QA & QC team and will fully track the orders from the very beginning to the very end to make sure all our customer get from us will be good.

Q8:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end.