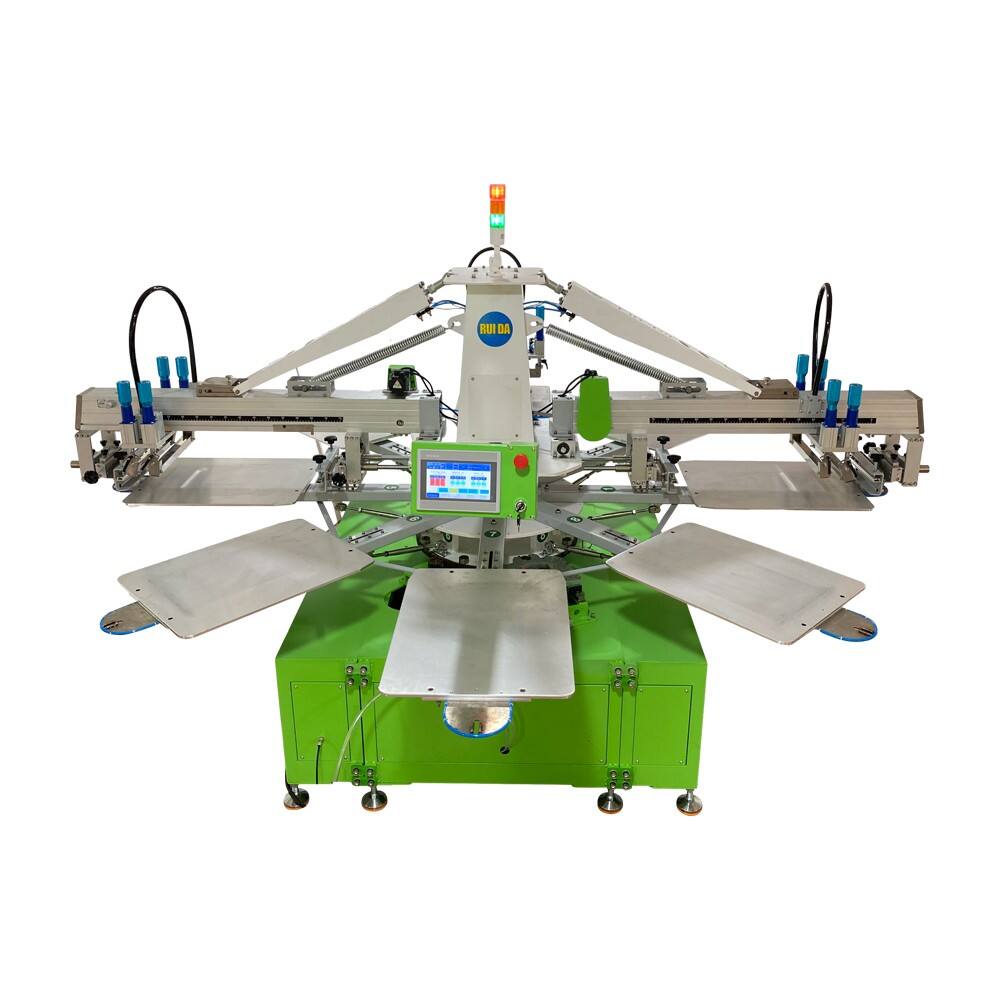

12 Color 12 Station Manual Mirco Registration Screen Printing Machine for Clothing Pure Cotton T-shirt

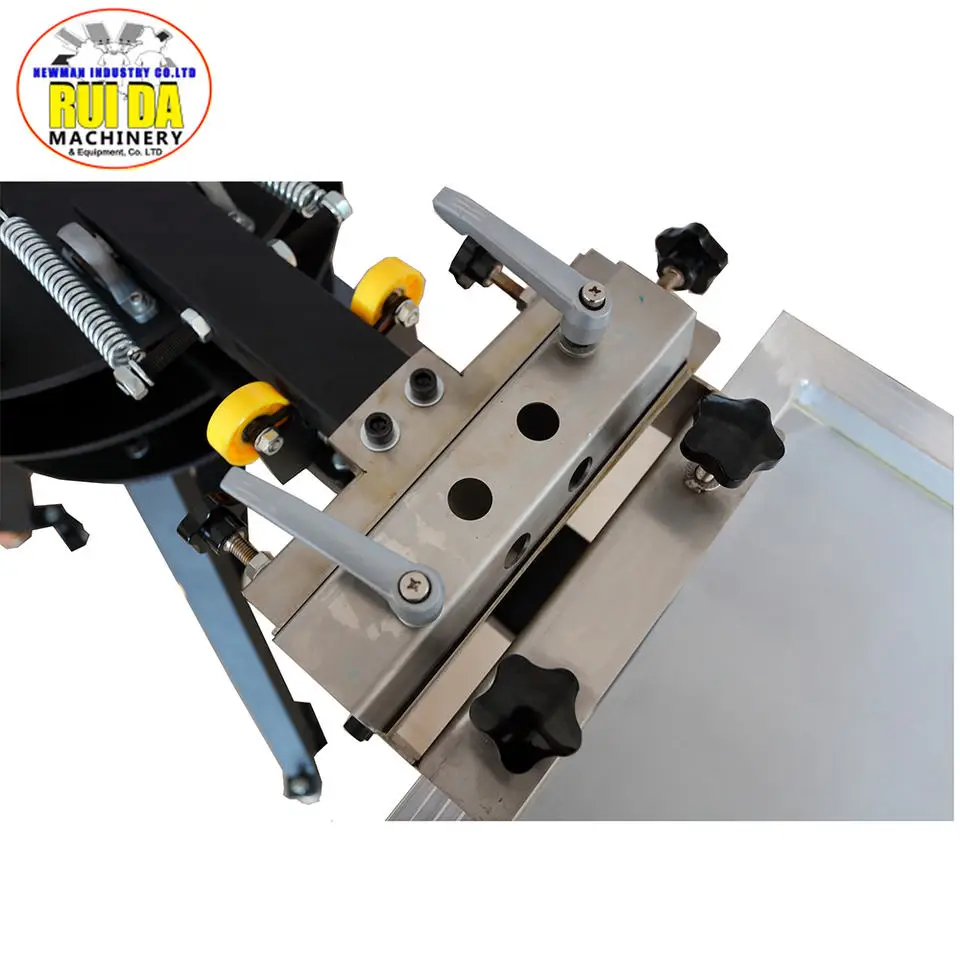

This professional 12-color, 12-station screen printing machine delivers exceptional precision and efficiency for your garment printing needs. Featuring micro-registration capabilities, it ensures perfect color alignment and crisp, detailed prints on pure cotton t-shirts and other clothing items. Built with durable materials and precise engineering, this versatile machine is ideal for both small print shops and larger commercial operations.

- Overview

- Related Products

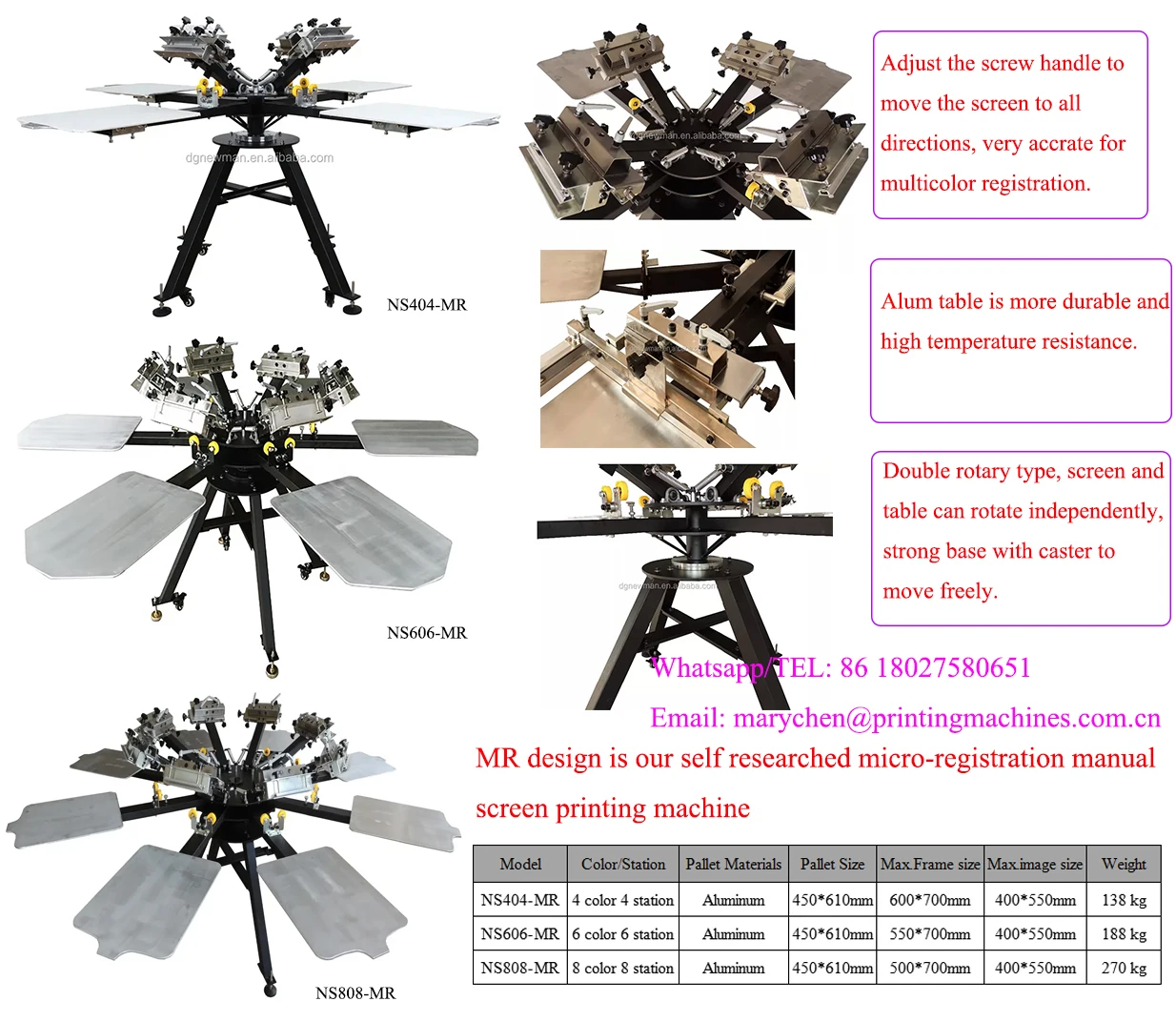

Model |

NS404-MR |

NS606-MR |

NS808-MR |

NS1010-MR |

NS1212-MR |

|||||

Platen size |

450*610mm |

450*610mm |

450*610mm |

450*610mm |

450*610mm |

|||||

Color/Station |

4 color 4 station |

6 color 6 station |

8 color 8 station |

10 color 10 station |

12 color 10 station |

|||||

Max frame size |

600*700mm |

550*700mm |

500*700mm |

500*700mm |

500*700mm |

|||||

Max printing area |

400*550mm |

400*550mm |

400*550mm |

400*550mm |

400*550mm |

|||||

Weight |

138kg |

188kg |

270kg |

420kg |

565kg |

|||||

Printing products |

T-shirt,cloth,clothing ,leather,backpack,towel,etc |

|||||||||

2.It is suitale for single color printing all kinds of cylindric product

3.Easy adjustment,easy operation, Nicely reliable

4.Max.printing area:200x240mm, Max.printing speed:500PCS/Hr

5:Easy adjustment,easy operation, Nicely reliable.

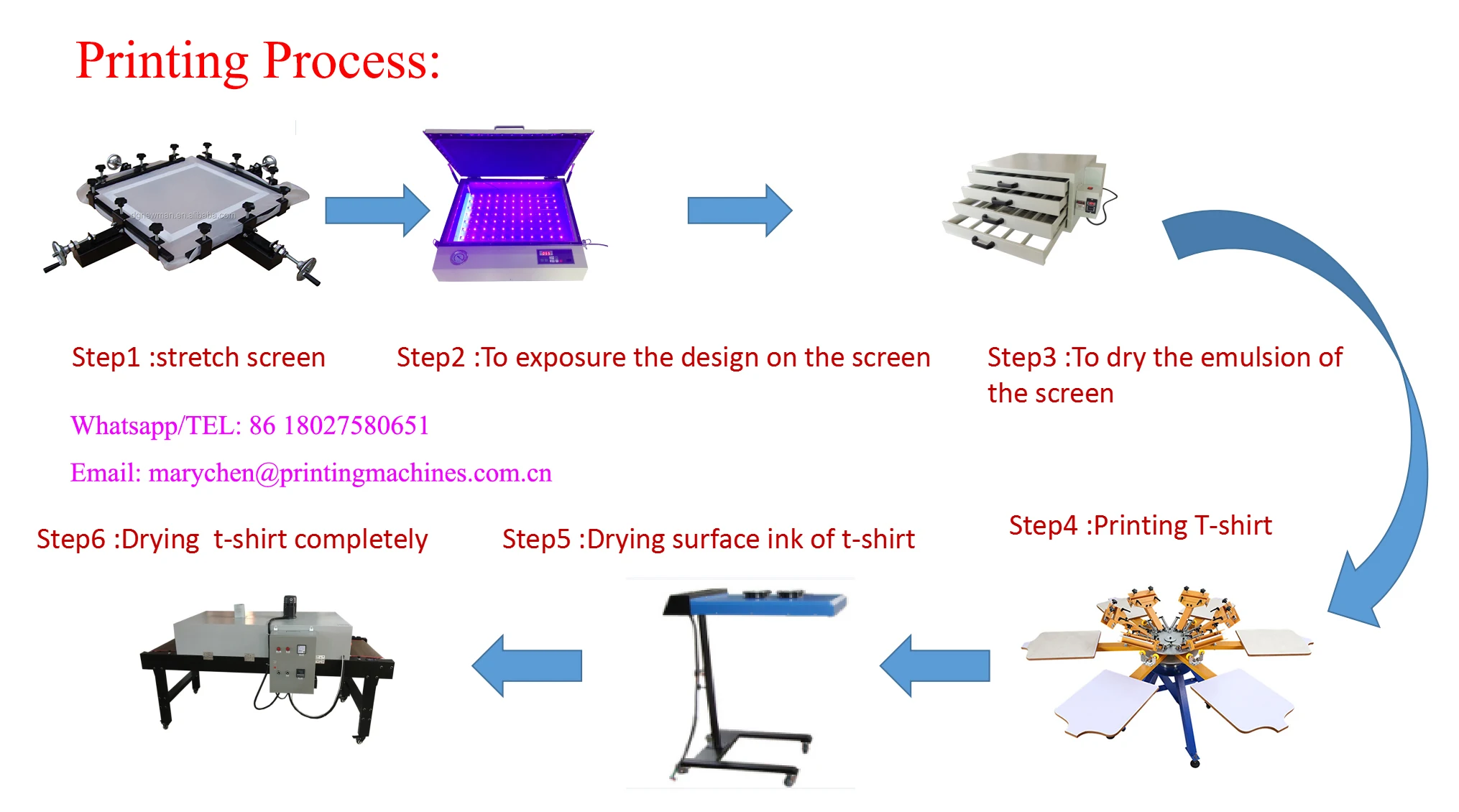

can stretch the silk screen evenly and flat,so it is the most important ancillary equipment for making screen stencil.

2. This equipment includes 4 gibs in 60cm, which can hold the frame within 60x60cm, the single 60x60cm and two sets can make

screen frame within 120cm,

2.Set a temperature of 65°C (under normal conditions)

3.Set drying time,when the temperature is 65 °C,drying the screen coated with our photosensitive emulsion for only one layer takes about 2 mins

Tips:

1.According to the heat resistant temperature of silk screen, the hightest temperature of this machine is 78°C or so.

2.Under normal Conditions,set a temperature of 65C is appropriate.

3.The real temperature may have 2-3 C different in temperature because of opening and closing the drawer,room temperature during the course of actual operation, which is normal and does not influence using.

4.This machine will indicate the last set parameters when it is used again because of the automatic date memory functions of the

equipped intelligent temp instrument

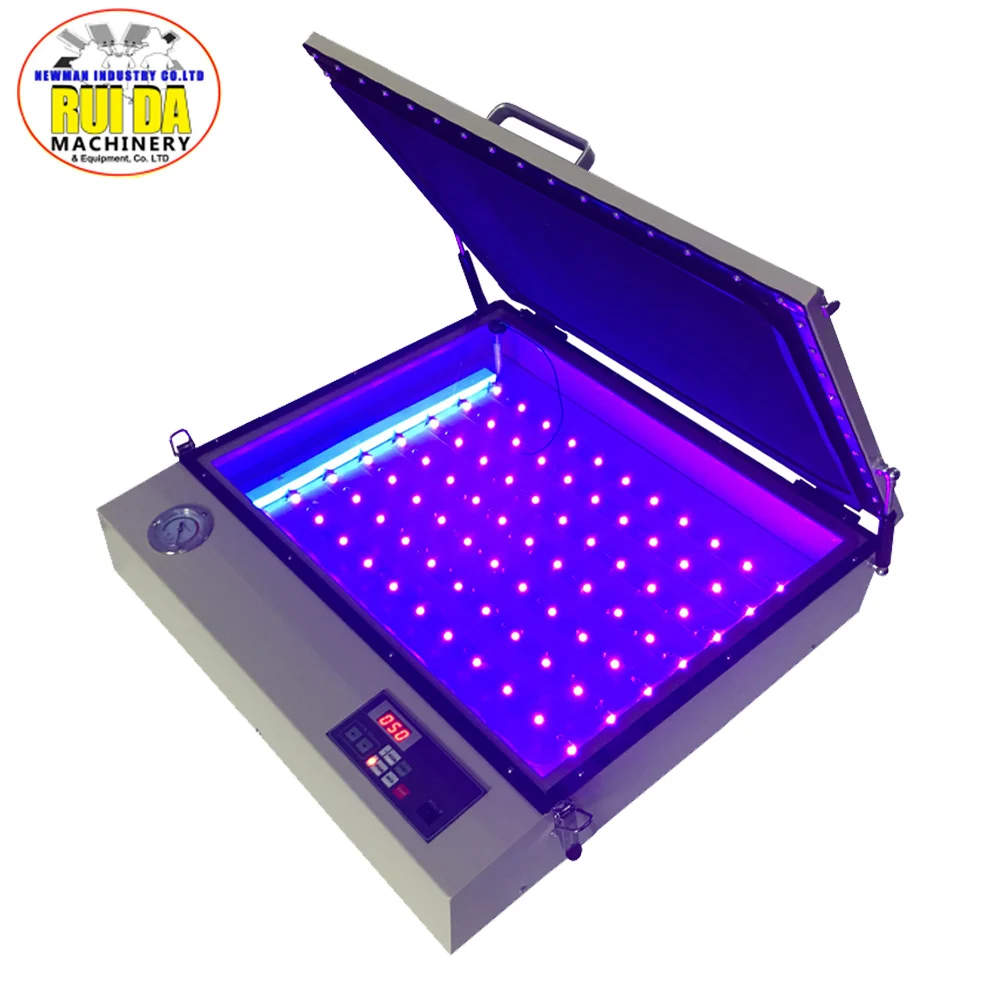

Used in the filed of plate-making such as pad printing steel plate,polymer plate, screen plate,hot stamper plate, when put the

film onto the plate into UV exposure machine,start it, the emulsion on the plate will appear a unseen imagine,this is important

process on all plate-making technology

Operation:

1. Put the film under the frame mesh and then close the lid 2.Turn on the POWER, set the vaccum time ,set the exposure time,press

start 3.exposure 4.After time is up,the machine stop working auto-matically,before opening the lid,the air should release

completely

1. Consistent heat radiation over the entire element surface ensures every print is properly flashed or cured.

2. Stainless steel screen covering element 360-degree swivel head

3.IR Automatic flash dryer with sensor

4.can work 3-4 hours continuously without stop

5.This flash dryer for screen printing sturdy base with wheels to move wherever you need

Application:

Feature The machine with sensor, when the platen coming, automatic turn on to working according to your setting time. Note: This

machine have no plug. you need to wiring with yourself Flash dryer gives you a full larger curing capacity as well as a possible

quicker flash time between colors. It can easily cure ink for silkscreen printing, can be used to flash dry your prints, and

process the final curing of your garments. The flash dryer base is compact, and will not tip over if bumped. Stop curing shirts

with a heat gun or an oven get this flash dryer and start drying your products the right way.

1.Heat exchanger ensures low air humidity to optimise drying efficiency

2.Variable conveyor speed for produce type and drying conditions

3.Reduced bacteria growth

4.Improved handling and increased shelf life

5Robustly built to withstand wet produce and variable conditions

6.Air circulation system through rollers to improve airflow around produce and reduce drying time

7.Soft pintle rollers at exit gently lower produce onto next piece of equipment Available in multiple sizes

Application:

The Tunnel Dryers are specially designed for the cure of inks on various materials. This dryer is available in various dimensions

due to the modular design. The specially developed airflow plate in this dryer ensures even heating over the whole drying area. It

uses the latest burner technologies. Due to this technology and attention to fuel efficient design, these dryers have a proven

record of low gas consumption. Optionally available with infrared, uv or electric elements. Besides that, the tunnel is easily

accessible for cleaning because of the lifting hood which is equipped with gas springs.